Manufacturer profile

We are a high aluminum ceramic ball manufacturer, because of years of focus, so the quality is more reliable. Also because of the direct manufacturer. So our prices are more realistic. Founded in 2014. Pingxiang Yongguang Chemical Filler Co., Ltd.. Located in Xiangdong Ceramic Industrial Park, Pingxiang City, Jiangxi Province, China, the annual production of various ceramic packing balls nearly 8500 tons, at present, the company has 106 employees, including college degree or above 12 people, professional and technical personnel 15 people, production management personnel 18 people, the company mainly produces a variety of ceramic chemical packing products, Products are widely used in metallurgy, coking, petrochemical, chemical fertilizer, pharmaceutical, acid production, thermal power generation and other industrial tower stuffing. All kinds of inert ceramic ball products produced by the company are exported to the United Kingdom, France, Italy, Morocco, the United States, Mexico, South Korea, the Philippines, Singapore, Japan and more than 20, and have been praised by customers.

Product overview

High aluminum ceramic ball is a kind of ceramic ball with high alumina (Al₂O) content, which is widely used in petrochemical, chemical, environmental protection and other fields as a catalyst support medium or grinding medium. According to the different content of alumina, high aluminum ceramic balls can be divided into 90%, 92%, 95%, 99% and other grades.

Composition and characteristics

High alumina content: Usually the alumina content is more than 80%-99%, the higher the alumina content, the better the performance of the ceramic ball.

High strength and hardness: with high compressive strength and Rockwell hardness, it can withstand greater pressure and impact, and is not easy to be worn, and performs well in grinding, crushing and other applications.

High temperature resistance: can withstand high temperature environment, can still maintain good physical and chemical properties at high temperature, not easy to deformation or softening, can be used in high temperature furnace and other equipment.

Good chemical stability: has excellent chemical corrosion resistance, acid, alkali, salt and other chemical substances have strong tolerance, can be used in a variety of harsh chemical environment.

Low expansion coefficient: The coefficient of thermal expansion is low, and the size of the sphere changes less in the case of large temperature changes, which helps to maintain the stability and accuracy of the equipment.

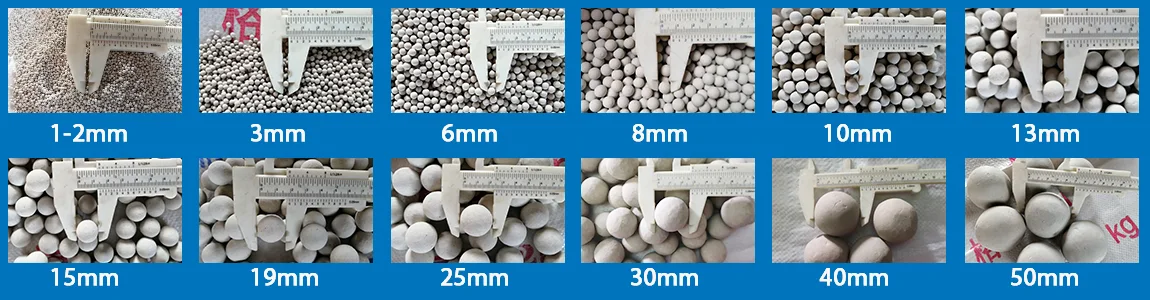

Common specification

Diameter: 3mm, 6mm, 3mm, 83mm, 10mm, 13mm, 15mm, 20mm, 25mm, 40mm, 50mm and other high aluminum ceramic ball specifications can be customized

High aluminum ceramic ball density:

90% Al₂O₃ : 3.6 g/cm³

92% Al₂O₃ : 3.7 g/cm³

95% Al₂O₃ : 3.8 g/cm³

99% Al₂O₃ : 3.9-4.0g /cm³

Water absorption: <8%

Compressive strength: 200-500 MPa (specific value depends on the diameter and Al₂O₃ content)

Application field

Catalyst support medium: in the petroleum, chemical, environmental protection and other industries, play the role of supporting and distributing catalysts, such as hydrogenation units, desulfurization and denitrification units.

Packing material: Used for chemical reaction tower, molecular sieve packing layer, optimize fluid distribution.

Selection guide

High aluminum ceramic ball alumina content: the higher the alumina content, the stronger the wear resistance, corrosion resistance and mechanical strength.

Small size (≤10mm) : suitable for small reactors.

Medium size (13-50mm) : often used for catalyst support.

Large size (≥50mm) : suitable for large flow and high pressure systems.

Reviews

There are no reviews yet.