Ceramic ball Density kg/m3

When it comes to the density of inert ceramic balls, people often ask about the kg/m3 of inert ceramic balls. So, how many kilograms of inert ceramic balls are there in a cube? What factors affect this? Will a higher or lower density affect their usage?

Density table

From the following table, we can see that the number of kilograms in each cubic unit of inert ceramic balls is mainly determined by the aluminum oxide content of the inert ceramic balls. The higher the aluminum oxide content, the greater the density, which means the weight of the inert ceramic balls per unit volume is heavier.

Technical Data

| Item | Type 1 | Type 2 | Type 3 | Type 4 |

| Equal to | Denstone 2000 | Denstone 57 | Denstone 99 | |

| AL2O3 | 17-19% | 23-26% | 90% | >99% |

| Acid resistance | >=98% | |||

| Alkali resistance | >80% | >82% | >90% | >95% |

| Thermal shock reistance | >=300 | >=400 | >=700 | >=800 |

| Operation temperature (℃) | 982 | 1100 | 1350 | 1500 |

| Bulk density(kg.m3) | 1250-1300 | 1300-1400 | 1600-1800 | 1900-2000 |

How does the density of the inert ceramic balls affect their usage?

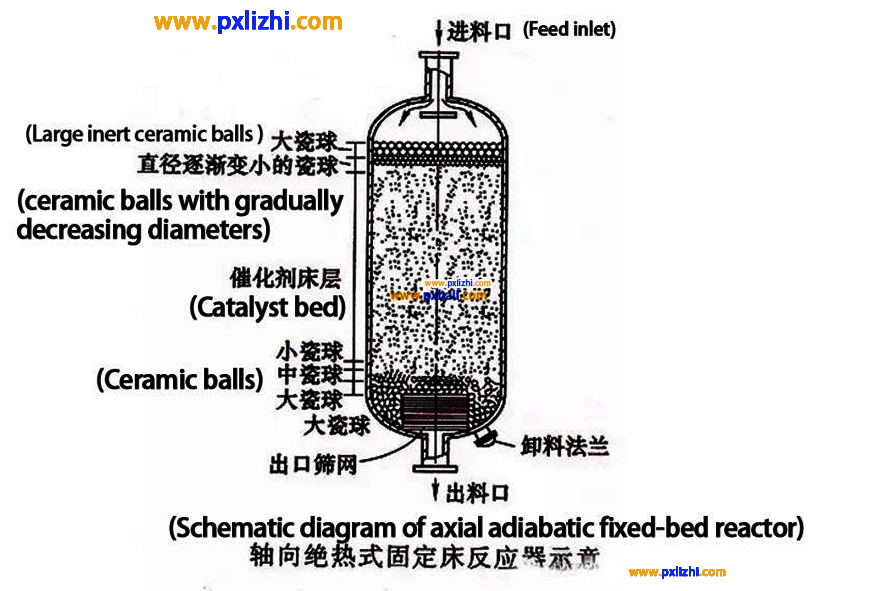

The influence of the density of the inert ceramic balls on their usage mainly manifests in the filling effect, mass transfer and heat transfer efficiency, and the stability of system operation: When the packing density is too high, the weight of the ceramic balls per unit volume is greater, which can enhance the uniform distribution effect of the fluid within the equipment and the support strength (such as when used as a catalyst support layer, it is more stable). However, it may increase the equipment load, and the gap between the balls becomes smaller, which is prone to causing an increase in fluid resistance, especially for high-viscosity fluids, leading to increased pressure drop and flow restriction problems; When the packing density is too low, the weight of the ceramic balls per unit volume is light, and the gap between the balls is large. Although it can reduce fluid resistance and reduce the equipment load, it may weaken the fluid distribution ability (it is prone to occur with biased flow), and the support stability decreases (such as the catalyst layer is prone to local collapse due to insufficient ceramic ball support). At the same time, when used as a grinding or dispersion medium, the low packing density will reduce the impact force, affecting the processing efficiency. In addition, the packing density is also related to the porosity of the ceramic balls and the composition of the raw materials. The adaptability needs to be comprehensively judged based on the fluid characteristics, equipment carrying requirements, and process goals of the specific application scenarios (such as reactor support, tower packing, grinding medium, etc.), in order to balance efficiency and stability.

strength and chemical composition.

| Crushing Strength (N/pellet) | 1/8”(3mm) | >350 | >350 | >510 | >510 |

| 1/4”(6mm) | >600 | >600 | >1500 | >1500 | |

| 3/8”(10mm) | >850 | >850 | >6000 | >6000 | |

| 1/2”(13mm) | >1850 | >1850 | >8000 | >8000 | |

| 5/8″(16mm) | >3600 | >3600 | >9000 | >9000 | |

| 3/4”(19mm) | >4870 | >4870 | >11000 | >11000 | |

| 1”(25mm) | >8500 | >8500 | >20000 | >20000 | |

| 1.5″(38mm) | >12000 | >12000 | >33000 | >33000 | |

| 2”(50mm) | >56000 | >56000 | >150000 | >150000 | |

| 3″(76mm) | >56000 | >56000 | >150000 | >150000 |

Chemical Analysis

| Al2O3 | SiO2 | MgO | K2O+Na2O | CaO | TiO2 | Leachable Fe2O3 |

| 23-26% | 62-72% | <1.0% | <4% | <1.5 % | <1.0% | <0.1% |