Preface

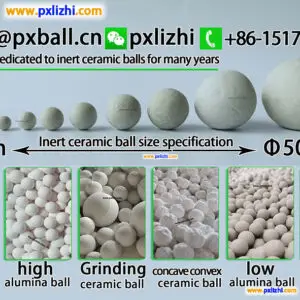

Our ceramic balls are not only cheap but also of reliable quality. This is because we are a factory that has specialized in the production of ceramic balls for many years, engaging in supply, wholesale, retail, etc. We offer a complete range of ceramic ball specifications and sizes, as well as a rich variety of types.

Price List

Wholesale price of low alumina ceramic balls: 430 – 570 USD/ton

Wholesale price of high alumina ceramic balls: 720 – 1300 USD/ton

Wholesale price of low alumina grinding ceramic balls: 650 – 770 USD/ton

Wholesale price of high alumina grinding ceramic balls: 800 – 1400 USD/ton

Note: The above prices are for reference only and are FOB prices. The packaging is standard export packaging. If iron drums or other packaging requirements are needed, the price will need to be recalculated.

Quotation

If you need an accurate quotation for ceramic balls, we need to know the quantity you require, the proportion of alumina content, packaging requirements, and the destination port for transportation, etc., in order to provide you with an accurate price. We will reply to your email within the earliest 1 hour and the latest 24 hours after receiving it.

Email: lizhi@pxball.cn

WeChat ID: pxlizhi

Company Name: Pingxiang Yongguang Chemical Filling Materials Co., Ltd.

Factors Affecting the Price of Ceramic Balls

Raw Material Costs: The main raw materials for ceramic balls include alumina, zirconia, silicon nitride, etc. The prices of these raw materials are influenced by market supply and demand, mineral resource reserves, and mining costs. For instance, if the price of alumina rises, the production cost of ceramic balls mainly made of alumina will increase, thereby pushing up the price.

Alumina Content: For inert alumina ceramic balls, the alumina content is a crucial factor determining the price. For example, common porcelain (15% – 20%), low-alumina porcelain (30% – 45%), medium-alumina porcelain (45% – 70%), high-alumina porcelain (70% – 90%), and corundum porcelain (≥ 90%), the higher the alumina content, the better the physical properties such as compressive strength, water absorption rate, and temperature resistance, and the higher the raw material cost and process requirements, resulting in a higher price.

Transportation and Packaging Costs: The distance of transportation, the choice of transportation methods, and packaging methods all affect the final price of ceramic balls. Long-distance transportation and special packaging requirements will increase costs, which will be reflected in the price.

From which aspects can the quality of inert ceramic balls be judged?

Alumina content: Confirmed through test reports, whether the content meets the claimed standards (for example, high alumina ceramic balls with 92% content should be measured to be ≥92%). The content directly affects the temperature resistance and corrosion resistance.

Mechanical strength: Tested with a compressive strength tester. The compressive strength of a single high alumina ceramic ball should be ≥5000N, and that of a low alumina ceramic ball should be ≥2000N. Insufficient strength can easily lead to breakage in working conditions.

Water absorption rate: The water absorption rate of high-quality ceramic balls should be ≤5%. A high water absorption rate indicates a loose internal structure, which can easily adsorb media and breed impurities, affecting equipment operation.

Appearance and dimensional accuracy: Can be initially judged by visual inspection and caliper measurement.

Appearance: The surface should be smooth without cracks, spots, or missing corners. If there are defects, it may be due to defects in the firing process, and it is prone to breakage from the defective areas during use.

Dimension: The diameter error of ceramic balls in the same batch should be ≤1mm. Uneven dimensions can lead to inconsistent filling gaps, affecting the uniformity of fluid distribution.

Temperature resistance and corrosion resistance: Verified through simulated working conditions or third-party testing.

Temperature resistance: Check whether the product can withstand the actual working temperature (for example, high alumina ceramic balls need to withstand 1500°C+). It can be judged by observing whether there is deformation or cracking after high-temperature burning.

Corrosion resistance: After soaking in the actual acid and alkali media used, test whether the ceramic balls show dissolution or surface peeling. High-quality ceramic balls should show no obvious changes.

Factory Advantage Introduction

We are a professional factory specializing in the production of inert ceramic balls. Due to our years of expertise, the quality is more guaranteed. As a factory direct sale, the price is more favorable. The production specifications range from 3mm to 50mm. Of course, if the quantity reaches the specified amount, custom production specifications are available, including the content of aluminum oxide. The varieties of inert ceramic balls we produce include concave-convex ceramic balls, perforated ceramic balls, low-aluminum ceramic balls, high-aluminum ceramic balls, grooved and perforated ceramic balls, multi-porous ceramic balls, etc. We usually have inventory of commonly used specifications of inert ceramic balls, which can meet the emergency shipping needs of customers.

Reviews

There are no reviews yet.