What Are the Best Inert Ceramic Balls?

The best inert ceramic balls—also known as catalyst support balls or inert support balls—are defined not by a single parameter or the lowest price, but by their optimal compatibility with specific operating conditions.

Truly high-quality inert alumina ceramic balls should be able to:

-

Ensure uniform fluid distribution inside the reactor

-

Provide stable and long-term support for catalysts

-

Reduce pressure drop, abrasion, and contamination

-

Maximize service life and optimize total life-cycle cost

Only when material composition, dimensional accuracy, mechanical performance, and application conditions are perfectly matched can inert ceramic balls be considered the “best” solution for a given process.

Key Criteria for the Best Inert Ceramic Balls

1. Clearly Define Operating Conditions

Before selecting inert ceramic balls, operating parameters must be identified, including:

-

Temperature (ambient or high temperature)

-

Process media (acidic, alkaline, or solvent environments)

-

Load conditions (static load or dynamic impact)

For example:

-

High-temperature and strongly corrosive conditions require corundum-based inert ceramic balls.

-

Cost-sensitive applications with low mechanical impact may use medium or low alumina inert ceramic balls.

2. Verify Core Performance Indicators

Suppliers should provide complete documentation, including:

-

Physical property test reports

-

Chemical composition analysis

-

Compressive strength test data

This helps prevent issues such as false purity claims or material substitution, ensuring product authenticity and reliability.

3. Pay Attention to Installation and Maintenance

Proper installation and maintenance are essential for long-term performance:

-

Ceramic balls should be clean and dry before loading

-

Install in layers from larger to smaller sizes according to particle diameter

-

Operators should stand on wooden boards during installation to avoid direct loading stress

-

Conduct annual inspections to check for fouling or blockage and clean or replace balls when necessary

4. Choose a Reliable Manufacturer

Priority should be given to manufacturers with many years of professional experience in producing inert ceramic balls. Suppliers offering customization options—such as special diameters or controlled porosity—are better suited to meet specific process requirements.

How to Choose the Best Inert Ceramic Balls?

1. Material Selection

Choose inert alumina ceramic balls with appropriate purity levels based on operating conditions. Alumina ceramic balls are suitable for most chemical environments and offer an excellent cost-performance ratio.

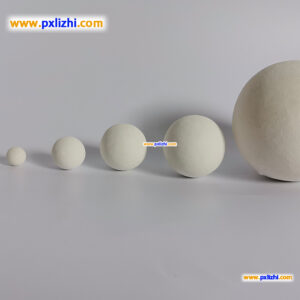

2. Size and Specification Matching

Select ceramic ball diameters (typically 1–50 mm) according to equipment size, fluid properties, and process design. A graded packing system can further optimize bed structure and reactor performance.

3. Quality Certification

Select manufacturers certified under ISO 9001 Quality Management Systems and capable of providing third-party inspection reports, ensuring accurate and traceable performance data.

4. Technical Support Capability

Professional suppliers that offer application consultation, installation guidance, and after-sales technical support help ensure inert ceramic balls perform at their highest potential throughout their service life.

How to Evaluate the Quality of the Best Inert Ceramic Balls?

The quality of inert ceramic balls should be assessed comprehensively based on four key dimensions: material purity, manufacturing precision, core performance, and inspection documentation.

1. Material and Chemical Composition

-

Verify the purity of main components such as alumina (e.g., ≥99% for high-purity alumina balls)

-

Confirm impurity levels through independent third-party test reports

-

Avoid products with material substitution or impurity dilution, which may lead to reduced chemical stability, media contamination, or performance degradation at high temperatures

2. Manufacturing Process and Dimensional Accuracy

-

Check diameter tolerance, sphericity, and surface finish

-

Prefer isostatic pressing for uniform density and strength

-

Ensure proper sintering quality with no visible pores, delamination, or cracks

Poor dimensional control or manufacturing defects can cause channeling, excessive pressure drop, and premature breakage.

3. Core Performance Indicators

Mechanical Properties

-

Compressive strength ≥ 850 MPa

-

High impact resistance, no easy crushing or edge chipping

Chemical Stability

-

Excellent resistance to acids and alkalis (except hydrofluoric acid)

-

No leaching or dissolution in organic solvents

Thermal Stability

-

Thermal shock resistance ≥ 15 cycles (rapid cooling from 800°C to 20°C)

-

Suitable for processes with frequent temperature fluctuations

4. Appearance and Inspection Documentation

-

Smooth and dense surface without visible cracks, pits, deformation, or abnormal color differences

-

Complete factory inspection reports, including composition, particle size, compressive strength, and abrasion resistance

-

Availability of third-party certification and traceable quality documentation

Products without proper inspection reports should be selected with caution.

Reviews

There are no reviews yet.