Preface

What are high-quality inert ceramic balls? In which aspects is the quality high? In which places must high-quality inert ceramic balls be used? The following will explain each point in detail.

Definition

High-quality inert ceramic balls are a type of inert carrier medium made from high-purity aluminum oxide (Al₂O₃) and other inorganic non-metallic materials as the main raw materials. They are produced through processes of batching, molding, and high-temperature sintering (the sintering temperature is usually between 1300 – 1700℃). Their core characteristic is extremely strong chemical stability, meaning they do not undergo chemical reactions with the treated medium under harsh conditions such as acids, alkalis, high temperatures, and high pressures. They also possess advantages such as high strength, low wear, and low impurity release. They are widely used in industrial fields such as petrochemicals, coal chemical industry, environmental protection, and pharmaceuticals, mainly serving to support catalysts and filter impurities.

Characteristics

Raw material purity: High-quality products usually use alumina with a purity of ≥ 92% (even 99% or higher high-alumina porcelain) or high-purity quartz sand, and strictly control the content of impurities (total impurity content ≤ 0.5%). Excessive impurities will cause the ceramic balls to dissolve ions in high-temperature or acid-base environments, polluting the raw materials or catalysts (for example, in petrochemicals, iron ions may cause catalyst poisoning).

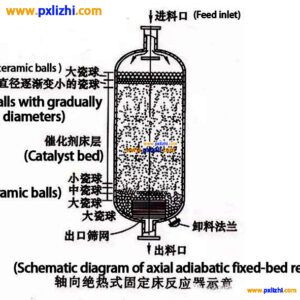

Excellent physical and mechanical properties: At room temperature, the compressive strength can reach 100 – 300 MPa (ordinary ceramic balls usually ≤ 80 MPa), capable of withstanding the weight of multiple layers of catalysts in the reactor (such as in the catalytic cracking unit of oil refining, the bottom ceramic balls need to withstand the pressure of tens of meters of catalysts), and not easily deform or break over a long period of use.

Chemical inertness and corrosion resistance: In a pH range of 1 – 14 (such as in acid-gas desulfurization devices in coal chemical industry, or alkaline reaction vessels in the pharmaceutical industry), it does not dissolve, oxidize or decompose, and will not release harmful substances into the medium, ensuring product purity and process stability.

High-temperature resistance and thermal stability: It can withstand temperatures of 400 – 1200℃ (depending on the material, high-alumina porcelain has better high-temperature resistance than ordinary porcelain), and the thermal expansion coefficient is small (≤ 8 × 10⁻⁶/℃), not prone to cracking when the temperature rises and drops sharply (such as during equipment start-up and shutdown), avoiding process interruption caused by the fragmentation of ceramic balls.

Extremely small size deviation: The diameter tolerance is controlled within ±0.1mm (the tolerance of ordinary ceramic balls can reach ±0.5mm), for example, for common 5mm and 10mm specifications, the diameter difference of each ball can be negligible. Uniform size ensures uniform gaps during filling, and the distribution of fluids (such as gases and liquids) is more stable, avoiding local flow velocity being too fast, resulting in catalyst scouring or efficiency decline.

No defects in appearance: The surface has no pores, cracks, or missing corners, the porosity is ≤ 1% (the porosity of ordinary ceramic balls can reach over 5%). The low porosity not only enhances strength and corrosion resistance, but also avoids media infiltration into the interior of the ceramic balls, leading to adsorption pollution, especially suitable for fields with extremely high hygiene requirements such as food and pharmaceuticals.

Application Location

Typical scenarios: Catalytic Cracking (FCC) units in oil refineries, hydrogenation refining units, ammonia synthesis and methanol synthesis reactors in coal chemical industries.

Reasons for using: These devices typically operate under high temperatures (300 – 800℃), high pressures (10 – 30 MPa), and in strong acid-base environments. The cost of catalysts is extremely high (several tens of thousands of yuan per ton). If ordinary ceramic balls are used, on the one hand, they are prone to break due to insufficient strength, and the debris will mix with the catalyst, causing catalyst poisoning and reduced activity, resulting in losses of tens of thousands of yuan; on the other hand, the release of impurities may pollute the oil or chemical products, leading to不合格 products (such as excessive sulfur content in gasoline). The low wear and high corrosion resistance of high-quality ceramic balls are the core guarantees for ensuring catalytic efficiency and product quality.

Technical Parameter

| Type | Inert Alumina Ball-99 | ||||||||||||

| Color | White | ||||||||||||

| Shape | Ball | ||||||||||||

| Chemical composition | Min. % | Max. % | Usual % | ||||||||||

| Al2O3 | 99 | 99.6 | 99.3 | ||||||||||

| SiO2 | / | 0.2 | 0.18 | ||||||||||

| Fe2O3 | / | 0.2 | 0.02 | ||||||||||

| TiO2 | / | 0.55 | 0.02 | ||||||||||

| CaO | / | 0.1 | 0.02 | ||||||||||

| MgO | / | 0.1 | 0.05 | ||||||||||

| Na2O | / | 0.25 | 0.1 | ||||||||||

| K2O | / | 0.2 | 0.13 | ||||||||||

| Physical properties | Leachable Iron (%) | ≤0.01 | |||||||||||

| Apparent Porosity by Weight (%) | ≤7.0 | ||||||||||||

| H2O absorption (wt.%) | <4.0 | ||||||||||||

| Acid resistance (%) | >99.8 | ||||||||||||

| Alkaline resistance (%) | ≥90 | ||||||||||||

| Bulk Density | (g/cm3) | 2.1 | |||||||||||

| (lb/ft3) | 131 | ||||||||||||

| Specific density | (kg/m3) | 3400 | |||||||||||

| (lb/ft3) | 212 | ||||||||||||

| Moh’s hardness (scale) | >8.0 | ||||||||||||

| Thermal conductivity (w/m2.k) | 0.7-0.8 | ||||||||||||

| Max. Operating Temperature | (℃) | 1550 | |||||||||||

| (℉) | 2822 | ||||||||||||

| Thermal expansion (%) (500℃) |

0.10 | ||||||||||||

| Thermal Shock Stability (times) (1000℃ then water cooling) |

10 | ||||||||||||

| Geometric properties | Nominal Size | (mm) | 3 | 6 | 10 | 13 | 16 | 19 | 25 | 38 | 50 | ||

| (inch) | 1/8 | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1.5 | 2 | ||||

| Crush Strength Min. | (lbs) | 115 | 230 | 440 | 1355 | 1720 | 3344 | 3432 | 4034 | 4960 | |||

| (kg) | 52 | 105 | 200 | 615 | 780 | 1520 | 1560 | 1830 | 2250 | ||||

| (N/PC) | 510 | 1030 | 1961 | 6031 | 7650 | 14896 | 15288 | 17946 | 22065 | ||||

Hint

Compared with ordinary inert ceramic balls, “high quality” does not merely mean higher purity of raw materials. Instead, it refers to achieving industrial-level standards in comprehensive performance, being able to meet the strict requirements of key processes for stability, safety, and efficiency, and avoiding production failures, raw material waste, or non-compliance with environmental standards due to insufficient product performance.

Reviews

There are no reviews yet.