Introduction

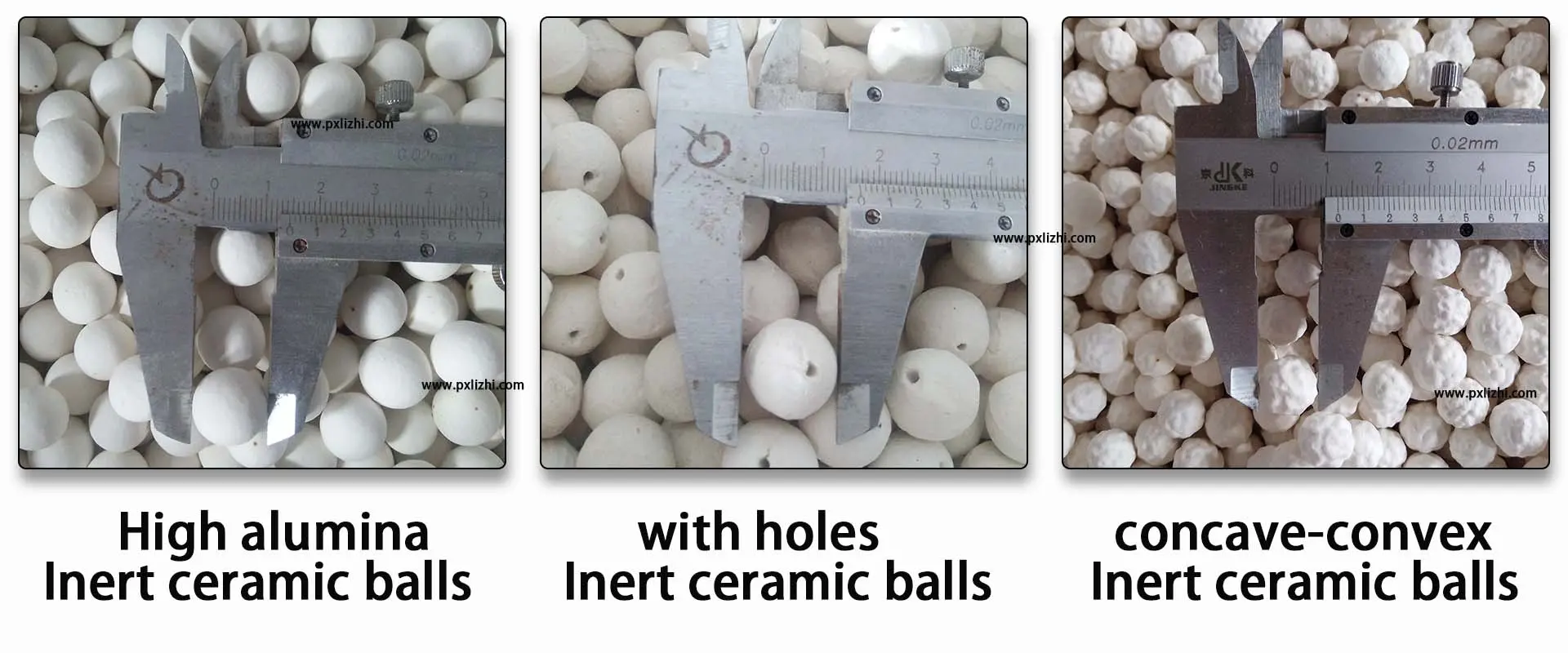

Inert balls (also known as inert ceramic balls) are functional spheres with stable chemical properties that do not undergo chemical reactions with the contacting medium. They are mainly made by high-temperature sintering of inert materials such as alumina, silicoaluminate, and corundum. Their core characteristic is “inertness”, meaning they do not participate in chemical reactions during the process, nor are they corroded or dissolved by the medium. At the same time, they possess physical properties such as high strength, high temperature resistance, and wear resistance.

Main functions:

- As a support structure: In reactors and towers, it supports catalysts or other fillers to prevent them from being damaged or collapsed due to gravity or fluid impact.

- Optimize flow field: Evenly disperse gas or liquid media to avoid channeling and improve reaction or separation efficiency.

- Protect equipment: Filled at the bottom or top of the equipment, it reduces the direct scouring of the fluid on the wall or serves as a filter layer to intercept impurities.

Application scenarios:

It is widely used in industries such as petrochemicals, coal chemicals, environmental protection, fertilizers, and metallurgy, for example, in catalytic cracking reactors, hydrogenation units, desulfurization towers, adsorption towers, etc. It is an auxiliary material that ensures the stable operation of processes.

Chemical composition

| Al2O3+SiO2 | Al2O3 | SiO2 | Fe2O3 | MgO | K2O+Na2O+CaO | Other |

| > 93% | > 17% | 60-70% | <1% | <0.5% | <4% | <1% |

Leach able Fe2O3is less than 0.1%

Physical properties

| Item | Value |

| Water absorption (%) | <0.5 |

| Bulk density (KGS/M3) | 1300-1450 |

| Specific gravity (g/cm3) | 2.3-2.4 |

| Free volume (%) | 40 |

| Operation temp.(max) (℃) | 1200 |

| Moh’s hardness (scale) | >6.5 |

| Acid resistance (%) | >99.6 |

| Alkali resistance (%) | >85 |

Crush strength

| Size | Crush strength | |

| Kgf/particle | KN/particle | |

| 1/8”(3mm) | >20 | >0.20 |

| 1/4”(6mm) | >50 | >0.50 |

| 3/8”(10mm) | >85 | >0.85 |

| 1/2”(13mm) | >180 | >1.80 |

| 3/4”(19mm) | >430 | >4.30 |

| 1”(25mm) | >620 | >6.20 |

| 1-1/2”(38mm) | >880 | >8.80 |

| 2”(50mm) | >1200 | >12.0 |

What is the general service life?

The service life of inert balls is usually 2 to 5 years, depending on the usage environment, material, and operating conditions.

Operating conditions: If used in high-temperature environments (such as above 1000°C), strong gas or liquid flow erosion (such as high-speed reactors), or in the presence of corrosive media (acids, alkalis, etc.), wear and erosion will accelerate, and the service life may be shortened.

If used in normal temperature, low flow rate, and clean medium conditions (such as ordinary catalyst supports), the service life can be longer.

Material differences: High-alumina inert balls (alumina content ≥ 90%) have higher hardness and stronger corrosion resistance, and their service life is usually longer than that of low-alumina or silica-alumina inert balls. Under the same operating conditions, the service life can be extended by 1 to 3 years.

Operation and maintenance: Avoid frequent start-stop of equipment (to reduce thermal shock damage), prevent impact from impurity particles, and maintain uniform fluid distribution, which can significantly extend the service life. Conversely, if there are problems such as flow deviation or bed collapse, it may lead to increased local wear and shortened service life.

Overall, the service life of inert balls is much longer than that of consumable materials such as catalysts. During daily maintenance, it is necessary to regularly check for damage and wear, and replace them locally when necessary to maintain normal function.

Reviews

There are no reviews yet.