Preface

We are a factory that sells low alumina balls. Not only are the prices low, but the quality is also guaranteed. As a professional direct factory with many years of experience, we have a complete range of low alumina balls in specifications and varieties, which can be neutral packaged, wholesale or retail. After reaching a certain quantity, we can also customize production.

Price advantage

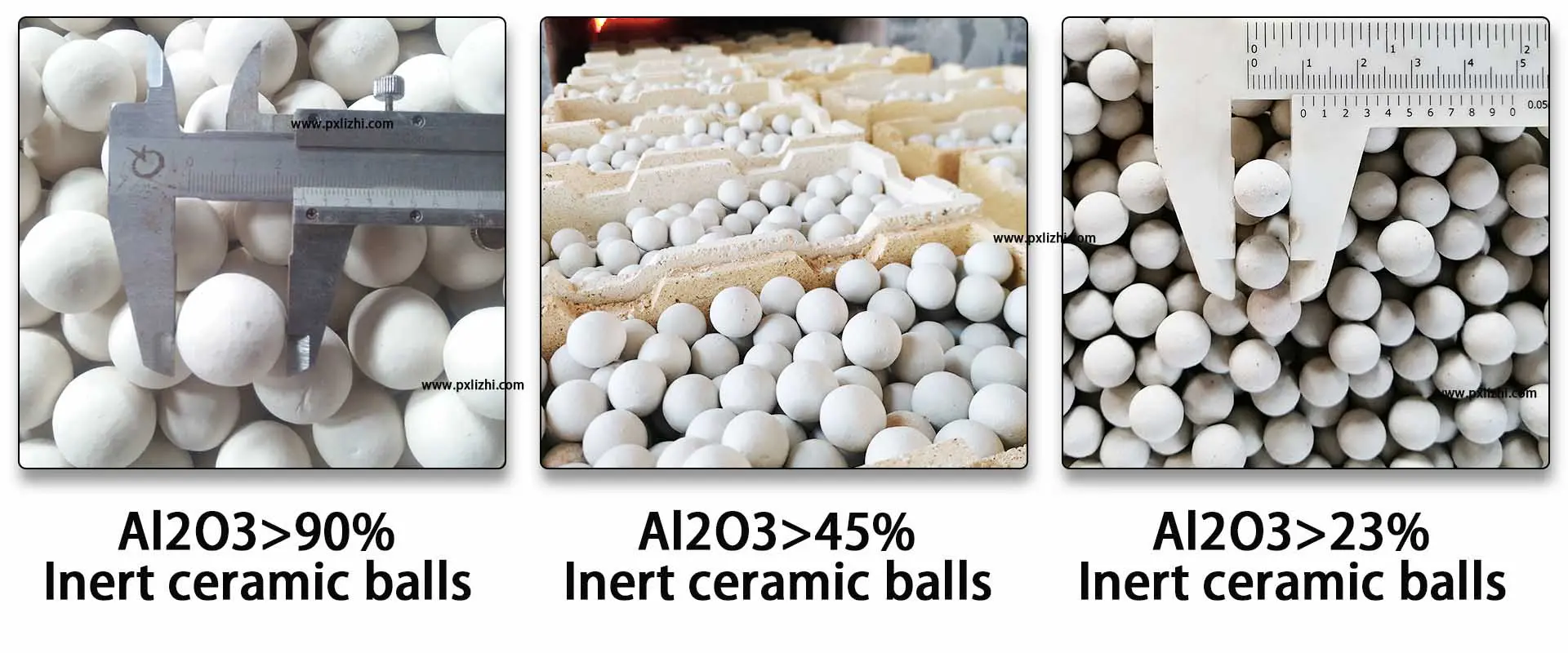

According to industry standards, the content of aluminium oxide in low-alumina balls is between 17% and 45%. Its main chemical component is silicon dioxide, followed by aluminium oxide. As the content of aluminium oxide directly determines the price of low-alumina balls, the price of low-alumina balls is around 400 US dollars per ton, while the price of high-alumina content inert ceramic balls is around 1,400 US dollars per ton. It is obvious compared to the price.

Chemical composition table

| Chemical Component | Content Range (wt%) | Description |

| Aluminum Oxide (Al₂O₃) | 17- 45 | The core active component that determines the basic strength and corrosion resistance of the ceramic balls. This content range corresponds to feldspar-mullite material. |

| Silicon Dioxide (SiO₂) | 50 – 68 | The main framework component, which works synergistically with Al₂O₃ to improve chemical stability. The total content of these two components must be ≥ 90%. |

| Iron(III) Oxide (Fe₂O₃) | ≤ 1.0 | A harmful impurity; excessive content will reduce the acid and alkali resistance of the ceramic balls. High-quality products can control this content to ≤ 0.3%. |

| Calcium Oxide + Magnesium Oxide (CaO + MgO) | ≤ 4.0 | Flux components; an appropriate amount can reduce the sintering temperature, while excessive content is prone to cause performance fluctuations. |

Suitable for the environment

It is worth noting that low-alumina balls are cheaper, but their overall performance still has significant differences compared to high-alumina inert ceramic balls. Therefore, when choosing the usage environment, such as temperature, pressure, and acid and alkali resistance, one needs to be cautious and careful.

For medium and small-sized chemical fertilizer plants (such as phosphate fertilizer and nitrogen fertilizer plants), acid mist absorption towers and ammonia water neutralization towers are used as packing support layers. In such scenarios, the concentrations of acids and bases are mostly at medium to low levels (such as sulfuric acid concentration ≤30%, sodium hydroxide concentration ≤20%), and the operating temperature is stable within the range of room temperature to 150℃. There is no need for the super corrosion resistance of high-alumina ceramic balls. The cost advantage of low-alumina ceramic balls (more than 20% lower than that of medium and high-alumina ceramic balls) can significantly reduce the procurement costs of enterprises.

Solvent recovery towers in small-scale fine chemical enterprises (such as methanol and ethanol recovery), used as packing spacer layers. This type of recycling has a small scale and low operating pressure. The low wear characteristic of low-aluminum ceramic balls (annual wear rate ≤0.1%) can meet the long-term usage requirements. Meanwhile, its price is only one-third of that of 316L stainless steel packing, which can control the overall investment in equipment.

Factory Introduction

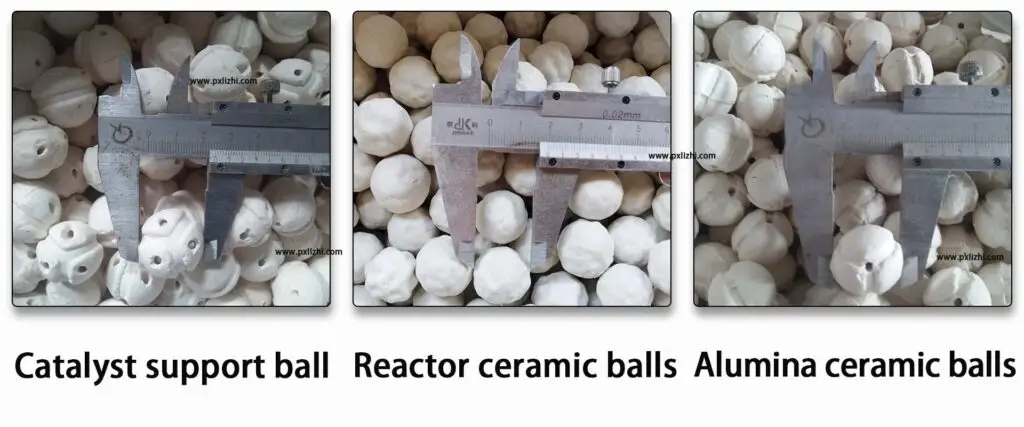

Pingxiang Yongguang Chemical Packing Co., Ltd. was established in 2014, specializing in the research and development, production and sales of inert alumina ceramic balls. Due to years of professional production experience, our products have obvious advantages in both quality and price. The specifications range from 3mm to 50mm, and the aluminum oxide content ranges from 17% to 99%. Other specifications, sizes and the content of aluminium oxide can all be customized and produced. The main varieties include low-alumina inert ceramic balls, medium-alumina inert ceramic balls, high-alumina inert ceramic balls, catalyst inert ceramic balls, open-cell inert ceramic balls, concave-convex inert ceramic balls, microporous inert ceramic balls, multi-hole inert ceramic balls, etc

Contact information

E-mail: pxlizhi@pxball.cn

Wechat ID: pxlizhi

Company website: www.pxlizhi.com

Low-Alumina vs. High-Alumina Inert Ceramic Balls

| Feature | Low-Alumina Inert Ceramic Balls | High-Alumina Inert Ceramic Balls |

| Alumina Content (Al₂O₃) | Low (typically 20% – 45%) | High (typically 90% – 99.9%) |

| Main Component | Clay, Kaolin | Industrial Alumina |

| Compressive Strength | Lower | Very High |

| Operating Temperature | Lower (typically up to 1300°C) | Very High (typically up to 1600°C) |

| Acid/Alkali Resistance | Good | Excellent |

| Abrasion Resistance | Good | Excellent |

| Cost | Lower | Higher |

| Typical Applications | Covering catalyst beds, distributing liquids/gases in moderate conditions. | Supporting catalysts in high-pressure reactors, high-temperature environments, tower internals. |

In summary: The choice depends on the operating conditions. High-alumina balls are used for high temperature, high pressure, and corrosive environments where maximum strength and inertness are critical. Low-alumina balls are a cost-effective solution for less severe conditions.

Reviews

There are no reviews yet.