Preface

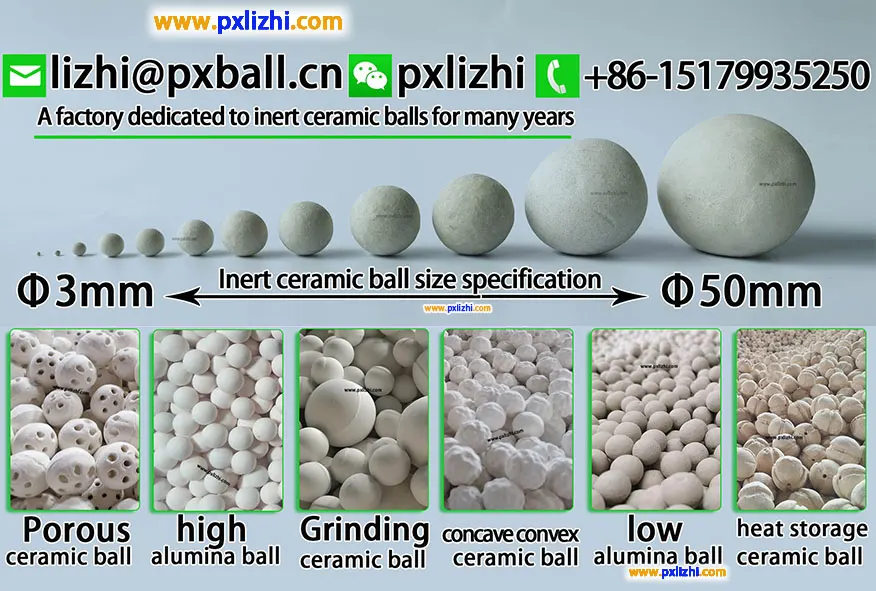

We have a significant advantage in terms of wholesale prices for ceramic balls. As an experienced ceramic ball manufacturer, we not only ensure product quality but also offer optimal prices. Additionally, we provide fast delivery services—we keep stock of commonly used inert ceramic balls and also support customization of various sizes, specifications, and different alumina (Al₂O₃) content levels.

Wholesale Price List

| Type of Ceramic Ball | Technical Parameters | Wholesale Price |

| Low-Alumina Inert Ceramic Balls | Al₂O₃ > 17% | $430 |

| High-Alumina Inert Ceramic Balls | Al₂O₃ > 90% | $1300 |

| Porous Inert Ceramic Balls | Al₂O₃ > 23% | $600 |

| Concave-Convex Inert Ceramic Balls | Al₂O₃ > 23% | $500 |

Note: The above prices are approximate. Specific quotations require confirmation of details such as purchase quantity, technical requirements, packaging method, and shipping port.

Factors Affecting Prices

- Alumina (Al₂O₃) Content: According to industry standards and technical parameters, the quality of inert ceramic balls improves as the alumina content increases. However, a higher alumina content requires a greater amount of alumina powder— the most expensive raw material in inert ceramic balls. Therefore, the alumina content directly determines the price of inert ceramic balls.

- Packaging Method: For the same batch of wholesale inert ceramic balls, the price difference between iron drum packaging and woven bag packaging is $140. Hence, the packaging method must be clarified before quoting.

- Purchase Quantity: “Larger quantity, better price” is a common practice in most industries, and inert ceramic balls are no exception. A larger purchase quantity helps save costs in transportation and other aspects, so the purchase quantity must also be specified for an accurate quotation.

Quality Identification

- Material Purity: Focus on the alumina content (low-alumina: 17%-23%, medium-alumina: 85%-92%, high-alumina: 92%-99%) and impurity (such as Fe₂O₃, SiO₂) content. High-purity products should have impurities ≤ 0.5%, which directly affects chemical inertness and stability.

- Mechanical Properties: Pay attention to room-temperature compressive strength (high-alumina products require ≥ 250MPa) and wear rate (high-quality products require ≤ 0.03%). Insufficient strength may lead to breakage, while high wear rate can cause dust pollution.

- Temperature and Corrosion Resistance: The long-term service temperature (high-alumina products: ≤ 1200℃), high-temperature strength retention rate (≥ 85% @ 800℃), and acid-base resistance range (high-alumina products: pH 1-14) must match the application scenario to avoid high-temperature cracking or acid-base corrosion.

- Physical Properties: Check the water absorption rate (high-quality products require ≤ 0.3%) and bulk density (high-alumina products: 3.2-3.6g/cm³). High water absorption rate makes the product prone to adsorbing impurities, while uneven density affects support stability.

- Appearance and Size: Inspect for cracks and missing corners. The particle size tolerance should comply with the standard of ±0.5mm – ±2mm. Excessive size deviation may cause uneven bed voids and fluid channeling.

Contact Information

- E-mail: lizhi@pxball.cn

- WeChat ID: pxlizhi

- Phone: +86-13979913701

- Website: pxlizhi.com

- Factory Address: Xiangdong Ceramic Industrial Park, Pingxiang City, Jiangxi Province, China

-

Wholesale Inert Alumina Ceramic Ball Prices

Reviews

There are no reviews yet.