Introduction

92% alumina inert ceramic balls are ceramic balls with alumina as the main component. They are named for their chemical inertness and non-participation in chemical reactions. Their alumina (Al₂O₃) content is greater than 92%, and they also contain small amounts of impurities such as silicon dioxide (SiO₂), iron oxide (Fe₂O₃), and magnesium oxide (MgO).

Chemical Composition

| Al2O3 | SiO2 | Fe2O3 | CaO+MgO | TiO2 | K2O+Na2O |

| ≥92% | ≤0.25% | ≤0.1% | ≤0.2% | ≤0.1% | ≤0.4% |

Physical properties

| Item | Value |

| Water absorption (%) | <8 |

| Bulk density (KGS/M3) | 1700-1800 |

| Specific gravity (g/cm3) | 2.3-2.4 |

| Operation temp.(max) (℃) | 1400 |

| Moh’s hardness (scale) | >6.5 |

| Acid resistance (%) | >99.6 |

| Alkali resistance (%) | >85 |

Application fields

It is widely used in industries such as petroleum, chemical engineering, fertilizer, gas, and environmental protection. In reactors, it serves as a catalyst coverage carrier material and tower packing. Its main function is to increase the distribution points of gas or liquid, support and protect catalysts with lower strength.

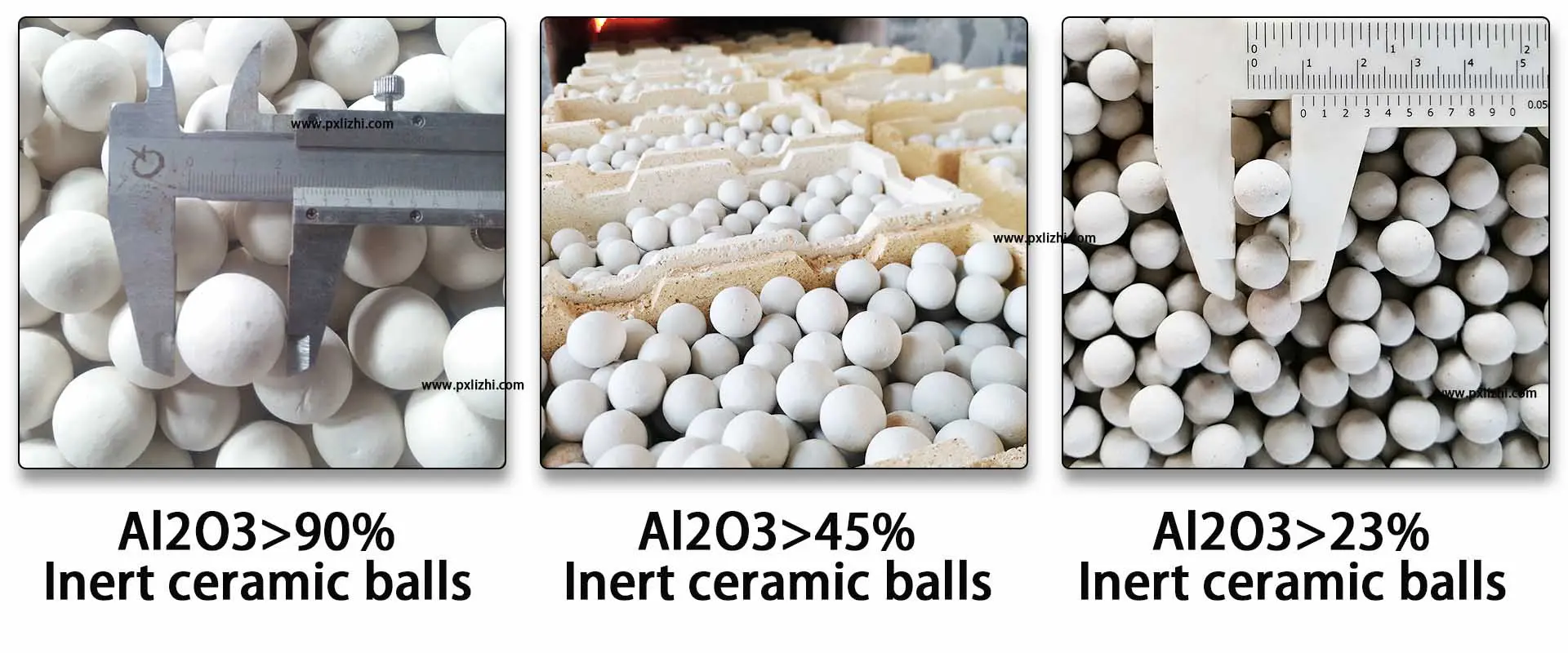

Comparison Table of Applicable Industries and Working Conditions for Inert Ceramic Balls with Different Alumina Contents

Low-Alumina Inert Ceramic Balls

Alumina Content: 30% – 45%

Applicable Industries: 1. Conventional sewage treatment filtration towers 2. Acid-base neutralization tanks under normal temperature and pressure 3. Low-concentration waste gas adsorption towers

Key Functions: 1. Supporting lightweight filter materials or adsorbents 2. Evenly distributing water flow / gas flow 3. Preventing clogging of lower layer fillers

High-alumina inert ceramic balls

Alumina content: ≥ 92%

Applicable industries: 1. Petrochemical hydrogenation cracking reactors 2. Special materials high-temperature sintering furnaces 3. Strong acid (such as sulfuric acid) / strong base (such as caustic soda) reaction towers

Key functions: 1. Withstand extreme high temperatures (1500°C+) and high pressure 2. Resist erosion by strong corrosive media 3. Maintain structural stability for a long time, without breaking and contaminating materials 4. Protect precious catalysts from impact

Why choose 92% alumina balls?

Choosing 92% inert alumina balls essentially achieves the best balance between demanding operating conditions and cost control. With a high alumina content of 92%, they possess a high-temperature resistance of over 1500°C, an acid resistance of ≥98%, and superior mechanical strength, making them suitable for high-end industrial scenarios such as petrochemical hydrocracking and strong acid and strong base reactions, while avoiding the contamination of materials due to the breakage of the balls. Compared to balls with higher alumina contents like 95% and 99%, they have lower raw material and firing costs, reducing cost waste while meeting core performance requirements. They also have a wide range of applications, covering most high-demand scenarios and compatible with medium to high-demand fields, eliminating the need for separate purchases for different operating conditions and simplifying selection and inventory management. Thus, they are a cost-effective choice that combines performance, cost, and versatility.

Reviews

There are no reviews yet.