Preface

We are a professional manufacturer of 92% alumina ceramic balls. Therefore, our products have more stable quality, lower prices, and are available for both wholesale and retail. We can also provide neutral packaging, emergency delivery, and customized production.

92% Function

92% alumina ceramic balls are named so because the alumina content is as high as 92%. The remaining components are a small amount of silica, magnesium oxide, calcium oxide, and other sintering aids. The addition of these sintering aids can effectively reduce the sintering temperature of the ceramics, promote uniform grain growth, and enhance the overall performance of the ceramic balls. The high content of α-alumina is the core foundation for its excellent hardness, strength, and other properties.

ChemicaI Composition

| Al2O3 | SiO2 | Fe2O3 | CaO+MgO | TiO2 | K2O+Na2O |

| ≥92% | ≤0.25% | ≤0.1% | ≤0.2% | ≤0.1% | ≤0.4% |

Size tolerance:

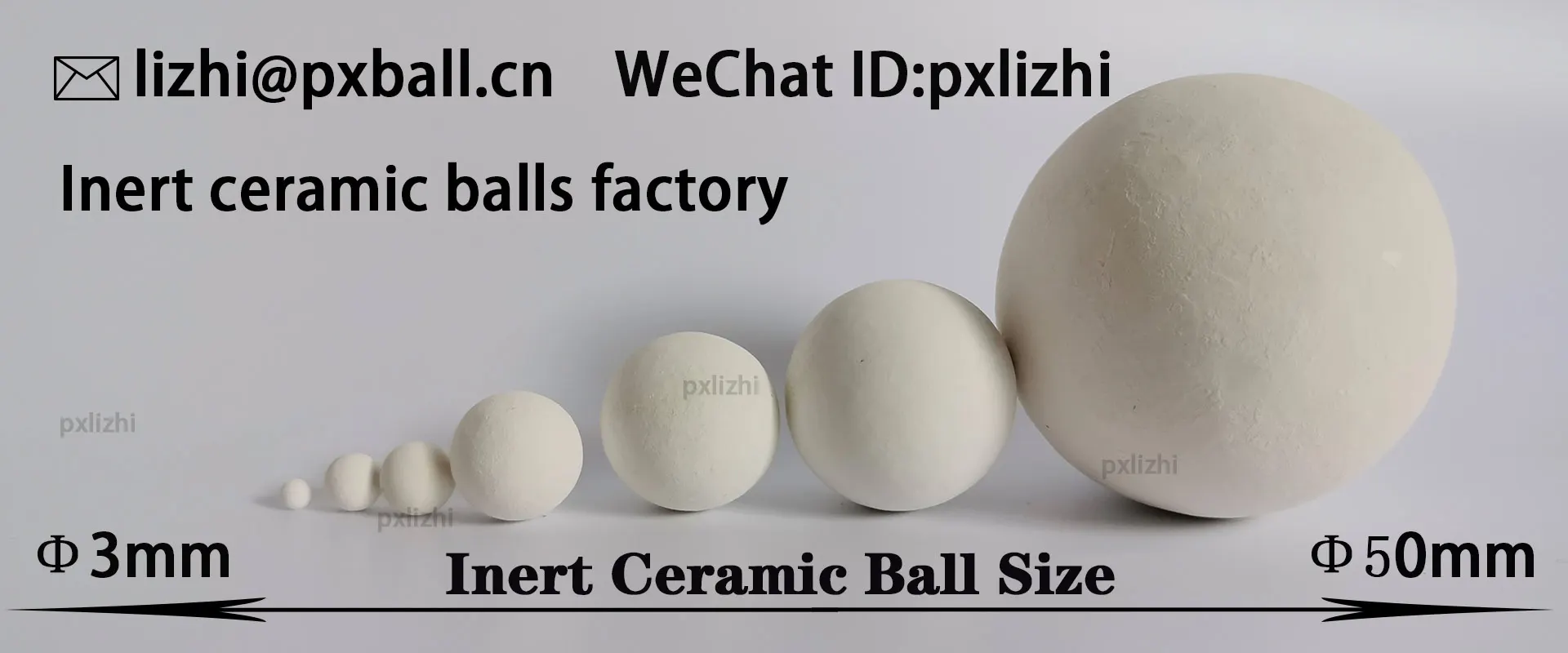

| Diameter Ф | 3 | 6 | 8 | 10 | 13 | 16 | 20 | 25 | 30 | 38 | 50 | 75 |

| Size tolerance | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||

Technical Data

| Item | Type 4 | |

| Equal to | Denstone 99 | |

| AL2O3 | >99% | |

| Acid resistance | ||

| Alkali resistance | >95% | |

| Thermal shock reistance | >=800 | |

| Operation temperature (℃) | 1500 | |

| Bulk density(kg.m3) | >=1900 | |

| Crushing Strength (N/pellet) |

1/8”(3mm) | >510 |

| 1/4”(6mm) | >1500 | |

| 3/8”(10mm) | >6000 | |

| 1/2”(13mm) | >8000 | |

| 5/8″(16mm) | >9000 | |

| 3/4”(19mm) | >11000 | |

| 1”(25mm) | >20000 | |

| 1.5″(38mm) | >33000 | |

| 2”(50mm) | >150000 | |

| 3″(76mm) | >150000 | |

Physical properties

High hardness: The Mohs hardness reaches level 9, second only to diamond. This makes the 92 aluminum oxide ceramic balls less prone to wear during the grinding process and able to maintain excellent grinding efficiency for a long time.

High strength: It has excellent compressive strength and flexural strength. The compressive strength is usually above 2000 MPa, and the flexural strength can also reach around 300 MPa. Under high pressure and impact loads, it is unlikely to crack or deform, and can work stably in harsh working conditions.

Excellent corrosion resistance: It has good corrosion resistance to various chemical media such as acids, alkalis, and salts. Except for a few strong corrosive media like hydrofluoric acid and concentrated phosphoric acid, it can stably exist in most chemical environments without undergoing chemical reactions and being corroded.

High temperature resistance: It can withstand high temperatures. The long-term operating temperature can reach above 1200℃, and the short-term operating temperature can even reach up to 1600℃. In high-temperature environments, its physical and chemical properties change little, and it will not undergo softening, melting, or decomposition, making it suitable for high-temperature calcination, high-temperature grinding and other process steps.

Good chemical stability: At both normal and high temperatures, it is unlikely to undergo chemical reactions with substances in the surrounding environment, does not release harmful substances, and does not interact with the materials being ground, ensuring that the chemical composition and properties of the materials are not affected.

Application fields:

Petrochemical industry: Mainly used in hydrogenation reactors and catalytic reforming reactors, serving as the catalyst support, carrying the catalyst and dispersing the reaction medium to prevent catalyst damage; also used in distillation towers and absorption towers, covering the packing layer to stabilize the gas flow and prevent pipeline blockage.

Coal chemical industry: Applied in gasification reactors and ammonia synthesis reactors, supporting the internal catalysts, ensuring uniform flow of the reaction medium, and assisting in the stable conduct of coal chemical synthesis reactions.

Support within reactors/reaction towers: As the catalyst support layer, placed below the catalyst, dispersing the gas/liquid flow and bearing the weight of the catalyst, preventing the catalyst from being crushed due to gravity, suitable for hydrogenation and reforming reaction equipment in petrochemical and coal chemical fields.

Coverage within distillation towers/absorption towers: Placed on the top or bottom of the packing layer in the tower, stabilizing the gas flow distribution, reducing the impact of liquid flushing on the packing, and preventing the powder of the packing from blocking the pipeline along with the medium flow, used in chemical separation and purification processes.

Reviews

There are no reviews yet.