Preface

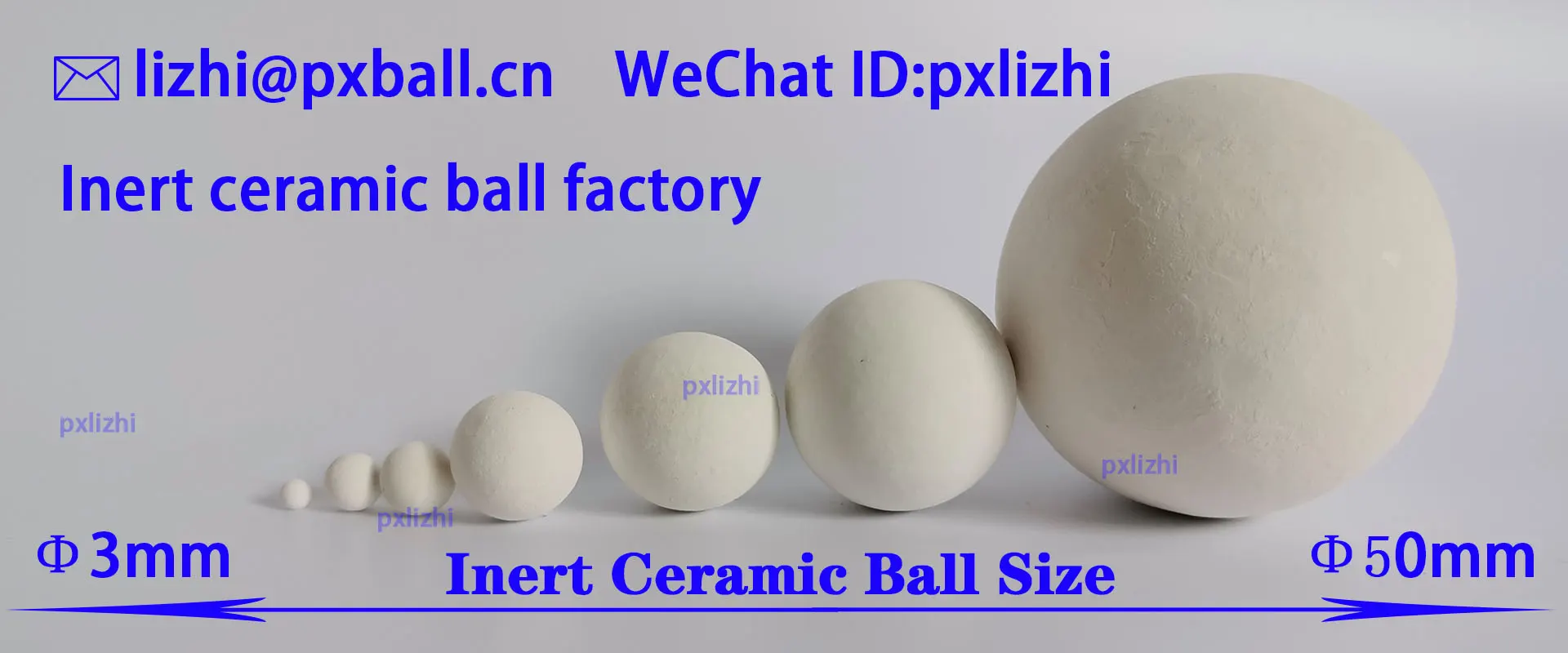

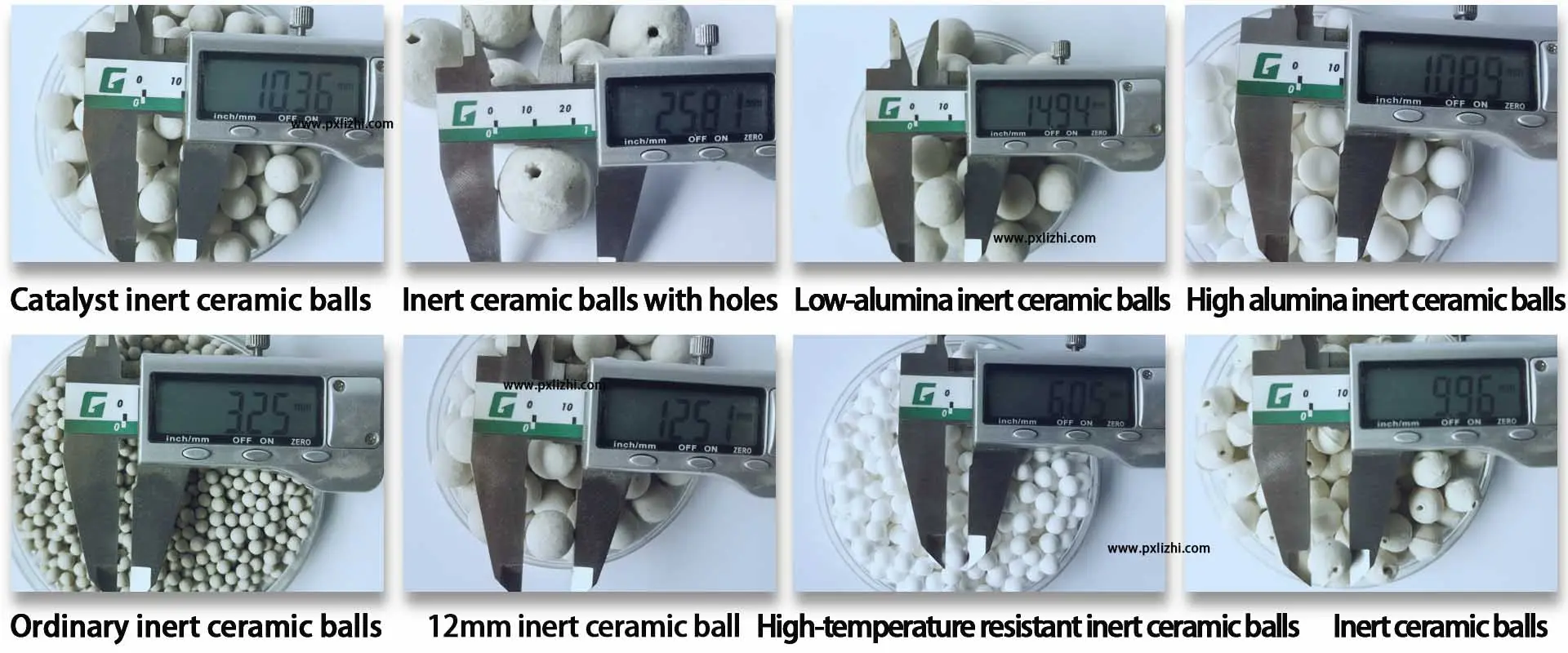

The following is the price list of Al2O3 ceramic balls. As it is a professional factory for many years, the quality is more reliable and the price is more advantageous. At the same time, we also support wholesale, retail, and customization of various specifications and sizes, as well as Al2O3 ceramic balls with different aluminum contents.

Price List

| al2o3 ceramic ball 23% Al₂O₃ | $470 | Minimum order quantity:0.5 ton |

| al2o3 ceramic ball 45% – 70%Al₂O₃ | $690 | Minimum order quantity: 0.5ton |

| al2o3 ceramic ball 90% Al₂O₃ | $1280 | Minimum order quantity: 0.5 ton |

| Porous inert alumina ceramic balls | $720 | Minimum order quantity: 0.5 ton |

Note: The above prices are wholesale prices. They are provided for your reference only. The specific technical requirements such as packaging and transportation distance are not clearly defined. Therefore, if you need accurate discount prices, please contact us. Of course, we will also provide you with good quality and reasonable prices.

Company Name: Pingxiang Yongguang Chemical Filler Co., Ltd.

Email: lizhi@pxball.cn

WeChat ID: pxlizhi

Factors affecting the price of Al2O3 ceramic balls

Aluminum content: The price of Al2O3 ceramic balls increases with the higher content of tricalcium aluminate. Naturally, the quality of the ceramic balls improves, so the quotation needs to clearly specify the level of tricalcium aluminate content.

Packaging method: The packaging methods of Al2O3 ceramic balls include pallets, iron drums, and ton packages, among others. The maximum price difference for one ton is as much as 110 US dollars.

Quantity: The larger the quantity, the better the price. If the quantity is small, the freight cost will be much higher. Therefore, the quantity also affects the price.

Delivery method and transportation method: The cost of delivery and transportation method, as well as the transportation distance, also need to be determined before the quotation. This also has an impact on the price.

How to judge quality

Specifications and dimensions impact: Excessive size deviation is likely to cause “bridging” during filling, affecting the flow of the medium; poor roundness will increase the pressure drop of the bed layer and reduce the mass transfer efficiency, especially more obvious in high flow rate conditions.

Surface qualified features: The surface should be smooth without obvious depressions, cracks, spots, no visible impurity particles (such as black or yellow impurities) with the naked eye, and the edges should have no sharp burrs (no scratch feeling when touched with hands).

Compressive strength: Insufficient strength will cause the ceramic balls to break in the load-bearing layer of the tower, and the resulting debris may clog the pipelines or contaminate the catalyst, increasing the equipment maintenance cost.

Chemical stability: If used in acidic conditions (such as sulfuric acid plants), the acid resistance rate not meeting the standard will cause the ceramic balls to be corroded and dissolved, releasing impurity ions that affect the reaction; for alkaline conditions (such as soda production), the focus should be on the alkali resistance rate.

Temperature resistance range: Ceramic balls with insufficient temperature resistance will soften and deform at high temperatures, causing the bed layer to collapse, seriously affecting the normal operation of the tower (such as coal chemical gasification towers need to withstand above 1400℃, and must select corundum material).

Reviews

There are no reviews yet.