Preface

We are a long-established factory specializing in China Al2O3 Ceramic Balls. Therefore, the quality of our Al2O3 ceramic balls is more stable and the prices are more favorable. We offer both wholesale and retail services, with a full range of commonly used specifications and sizes available to meet urgent shipping needs. Custom production is also available.

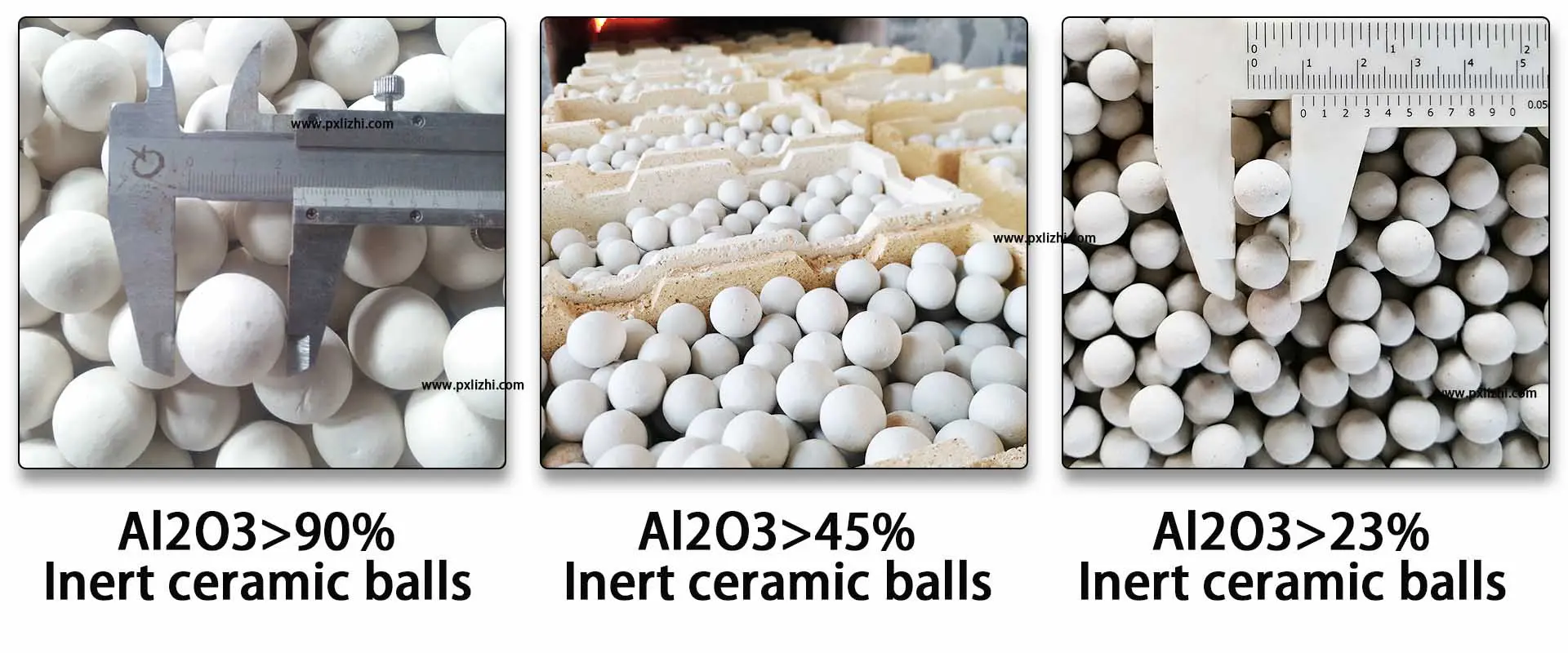

Why is the Al₂O₃ content emphasized for inert ceramic balls?

The Al₂O₃ content is highlighted for inert ceramic balls because, as the core component of ceramics, it directly determines the strength, hardness, and wear resistance of the balls. The higher the content, the denser the structure of the ceramic balls, and the stronger their impact and pressure resistance, which enables them to better meet the support and filling requirements in reactors and other scenarios, ensuring stability and durability during use.

Technical Data

| Item | Type 1 | Type 2 | Type 3 | Type 4 | |

| Equal to | Denstone 2000 | Denstone 57 | Denstone 99 | ||

| AL2O3 | 17-19% | 23-26% | 90% | >99% | |

| Acid resistance | >=98% | ||||

| Alkali resistance | >80% | >82% | >90% | >95% | |

| Thermal shock reistance | >=300 | >=400 | >=700 | >=800 | |

| Operation temperature (℃) | 982 | 1100 | 1350 | 1500 | |

| Bulk density(kg.m3) | 1300-1400 | 1400-1500 | 1600-1800 | >=1800 | |

| Crushing Strength (N/pellet) |

1/8”(3mm) | >350 | >350 | >510 | >510 |

| 1/4”(6mm) | >600 | >600 | >1500 | >1500 | |

| 3/8”(10mm) | >850 | >850 | >6000 | >6000 | |

| 1/2”(13mm) | >1850 | >1850 | >8000 | >8000 | |

| 5/8″(16mm) | >3600 | >3600 | >9000 | >9000 | |

| 3/4”(19mm) | >4870 | >4870 | >11000 | >11000 | |

| 1”(25mm) | >8500 | >8500 | >20000 | >20000 | |

| 1.5″(38mm) | >12000 | >12000 | >33000 | >33000 | |

| 2”(50mm) | >56000 | >56000 | >150000 | >150000 | |

| 3″(76mm) | >56000 | >56000 | >150000 | >150000 | |

Size tolerance

| Diameter Ф | 3 | 6 | 8 | 10 | 13 | 16 | 20 | 25 | 30 | 38 | 50 | 75 |

| Size tolerance | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||

What is the optimal range of Al₂O₃ content in inert ceramic balls?

The optimal range of Al₂O₃ content in inert ceramic balls depends on the specific application. Generally, for common support and filling purposes where cost is a concern, the content is typically between 23% and 70%. If higher strength and wear resistance are required to withstand high pressure and high flow rates in harsh environments, the optimal range is usually between 70% and 99%. Although a higher content (such as over 95%) offers better performance, it significantly increases the cost and reduces the cost-effectiveness. Therefore, a balance must be struck between performance and cost.

Factors Affecting Prices

- The content of alumina (Al2O3) has a direct proportional relationship with the price.

- Packaging requirements: Al2O3 ceramic balls are packaged in woven bags, bulk bags, iron drums, etc., and the prices vary greatly.

- The quantity purchased also directly affects the price of Al2O3 ceramic balls, which is understandable to everyone.

- Transportation distance and mode also have a significant impact on the price.

For quotations, please contact us via email: lizhi@pxball.cn or WeChat: pxlizhi.

Reviews

There are no reviews yet.