Definition

Filled ceramic balls are solid spheres with regular geometric shapes (commonly circular and cylindrical), which are made from inorganic non-metallic materials such as kaolin and alumina as the main raw materials through processes like batching, molding, and high-temperature sintering. With its outstanding physical and chemical properties, it plays a key role in multiple industries such as petrochemicals, metallurgy, environmental protection, and building materials. It can not only optimize the efficiency of the reaction or separation process, but also reduce the operating cost of the equipment and extend the service life of the core components.

Performance characteristics

1.Excellent chemical stability

Except for strong acids and alkalis (such as concentrated hydrochloric acid and hydrofluoric acid), most filled ceramic balls (especially high alumina balls and inert ceramic balls) can resist the corrosion of organic acids, inorganic salt solutions, organic solvents and other media. They are also less likely to undergo chemical decomposition in environments with large temperature fluctuations, making them suitable for highly corrosive working conditions such as petroleum refining and coal chemical industry.

Inert ceramic balls hardly react with any medium and can serve as an “isolation layer” to prevent the mixture of different media or protect the inner walls of equipment from corrosion.

- High hardness and wear resistance

The Mohs hardness of high alumina balls can reach 9 (second only to diamond), and their compressive strength can reach 1500-3000 mpa. During long-term use, the wear rate is extremely low (usually less than 0.01% per year), which can effectively reduce the impurities caused by wear from mixing into the material and ensure the purity of the product

- Good thermal stability and heat insulation

The high-temperature resistance of the filled ceramic balls is excellent. High-alumina balls can be used for a long time at temperatures below 1200℃, and special ceramic balls can even withstand temperatures up to 1600℃. They are suitable for filling or insulation in high-temperature equipment such as cracking furnaces and hot blast stoves.

- Regular geometric shapes and uniformity

When industrial-grade filled ceramic balls are stacked, they can form a uniform pore structure, ensuring the uniform distribution of fluids (gases or liquids), avoiding the phenomena of “channel-flow” and “diversion flow”, and improving the efficiency of reactions or separation (such as fluid distribution in distillation columns and adsorption columns).

Chemical composition

| Al2O3+SiO2 | Al2O3 | SiO2 | Fe2O3 | MgO | K2O+Na2O+CaO | Other |

| > 93% | > 17% | 60-70% | <1% | <0.5% | <4% | <1% |

Leach able Fe2O3is less than 0.1%

Physical properties

| Item | Value |

| Water absorption (%) | <0.5 |

| Bulk density (KGS/M3) | 1300-1450 |

| Specific gravity (g/cm3) | 2.3-2.4 |

| Free volume (%) | 40 |

| Operation temp.(max) (℃) | 1200 |

| Moh’s hardness (scale) | >6.5 |

| Acid resistance (%) | >99.6 |

| Alkali resistance (%) | >85 |

Crush strength

| Size | Crush strength | |

| Kgf/particle | KN/particle | |

| 1/8”(3mm) | >20 | >0.20 |

| 1/4”(6mm) | >50 | >0.50 |

| 3/8”(10mm) | >85 | >0.85 |

| 1/2”(13mm) | >180 | >1.80 |

| 3/4”(19mm) | >430 | >4.30 |

| 1”(25mm) | >620 | >6.20 |

| 1-1/2”(38mm) | >880 | >8.80 |

| 2”(50mm) | >1200 | >12.0 |

Application scenarios

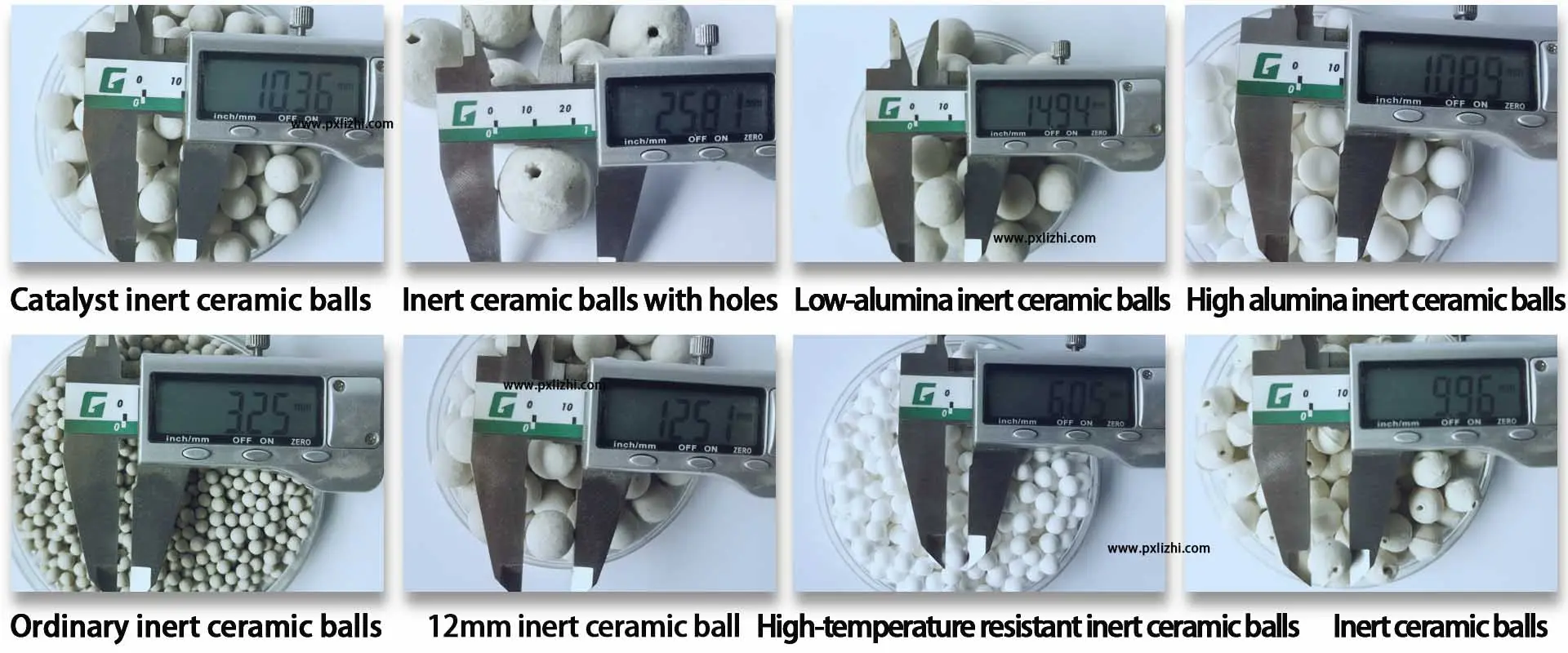

Based on the above performance characteristics, filled ceramic balls have been widely used in multiple industrial fields. Different types of ceramic balls correspond to different application requirements. The specific scenarios are as follows:

- Petrochemical and coal chemical industries

Catalyst support and protection: In the reactors of hydrocracking, catalytic reforming and other units, high alumina balls or inert ceramic balls are used as the support layer (bottom) and covering layer (top) of the catalyst. The bottom support layer bears the weight of the catalyst to prevent it from leaking into the bottom of the equipment. The top covering layer evenly distributes the reaction raw materials and protects the catalyst from being eroded and worn by the airflow at the same time.

Filling of distillation columns and absorption columns: Inert ceramic balls are used as packing supports in distillation columns or as “distributors” to optimize the liquid spray effect, reduce local liquid accumulation in the column, and improve separation efficiency. In desulfurization towers and decarbonization towers, porous ceramic balls can adsorb sulfides and carbon dioxide in flue gas, assisting in meeting environmental protection standards.

Key indicators for selection

Material selection: Choose based on the corrosiveness of the medium and temperature – for strong corrosiveness and high temperature, select high alumina balls (with over 95% alumina). Inert ceramic balls are recommended for non-corrosive use at room temperature.

Size selection: It is determined based on the diameter of the equipment and the function of the filling layer – the support layer usually selects a larger size (such as 50-80mm), while the covering layer or distribution layer selects a smaller size (such as 10-25mm). The smaller the diameter of the equipment, the smaller the size of the ceramic balls should be to avoid excessive accumulation gap causing medium deviation flow.

Strength and wear resistance: For scenarios with high purity requirements (such as pharmaceuticals and electronics), high hardness and low wear rate high alumina balls (wear rate < 0.005% per year) should be selected. For high-pressure equipment with high strength requirements (such as hydrogenation reactors), ceramic balls with a compressive strength greater than 2000MPa should be selected.

Reviews

There are no reviews yet.