Factory Introduction

We are a professional manufacturer specializing in high-density inert alumina balls, with nearly 20 years of experience in this field. Our products offer more stable quality and more competitive pricing, making us a preferred partner for clients in petrochemical, environmental protection, metallurgy, and other industries. We are committed to providing reliable packing solutions for industrial applications.

Core Product Advantages

As our flagship product, high-density inert alumina balls are manufactured using premium raw materials and mature production technology, offering four key advantages:

High-Quality Material:

Made from high-purity alumina, ensuring high hardness, compact structure, and stable physical and chemical properties.

Outstanding Performance:

Highly resistant to high temperatures (withstanding 1100℃–1600℃ or above), acid-alkali corrosion, and abrasion. The balls remain chemically inert under complex working conditions, ensuring long-term stable equipment operation.

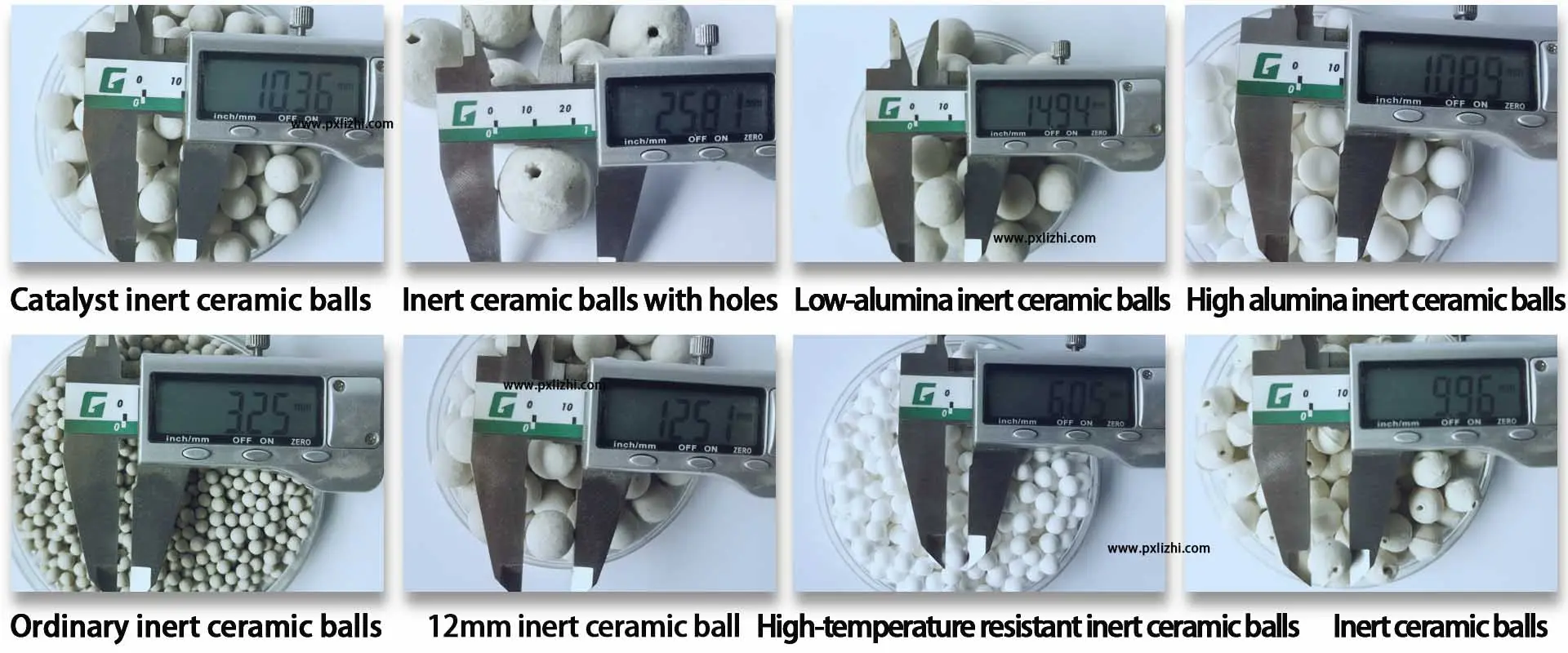

Wide Range of Specifications:

Available in common sizes from 3–50 mm, and customizable upon request to fit different reactors, towers, and installation requirements.

Core Applications:

Mainly used for support, covering, and filtration inside industrial equipment—such as supporting catalysts, distributing media evenly, and filtering impurities—to enhance equipment efficiency and service life.

Factory Strengths & Assurance

Production Capacity & Supply:

Equipped with standardized production lines and an annual capacity of 6,000 tons, enabling quick order response and ensuring customers’ production schedules.

Quality Control:

A complete quality inspection system is established, covering raw material selection, processing, and finished-product testing. Each batch undergoes hardness, temperature resistance, particle size, and other inspections to ensure quality compliance.

Price Advantage:

Factory-direct supply eliminates middleman distribution costs, ensuring high-value, cost-effective products without compromising quality.

Service Support:

We offer one-stop services, including technical consultation, specification customization, and logistics arrangements. Our after-sales team provides timely support to address any issues during use.

Looking ahead, we will continue to uphold the philosophy of “quality first, customer foremost,” optimizing production processes, enhancing product performance, and providing superior inert alumina ball products and services to customers across more industries.

Price List

| Product Grade | Alumina Content (Al₂O₃) | Bulk Density | Temperature Resistance (℃) | Note: Prices above are for reference only. Final pricing depends on technical parameters, order quantity, packaging requirements, etc. |

|---|---|---|---|---|

| Ordinary Low-Alumina Inert Balls | 17%–23% | 1.25–1.30 | ≥1100 | |

| Medium-Alumina Inert Balls | 25%–45% | 1.30 | ≥1200 | |

| High-Alumina Inert Balls (High Density) | 46%–70% | 1.4–1.6 | ≥1300–1500 | |

| Corundum-Type High-Alumina Balls | ≥90% | 1.8–2.0 | ≥1600 |

Benefits of High Density

The key advantage of high-density inert alumina balls lies in their higher bulk density (typically ≥2.6 g/cm³), which delivers superior mechanical strength and working-condition adaptability. Their compact structure and higher hardness dramatically improve wear resistance and compressive strength, reducing breakage and extending service life.

They offer exceptional resistance to high temperatures (up to 1700℃ or more) and acids/alkalis, making them ideal for harsh industrial environments such as petroleum catalytic cracking and high-pressure reactors. They ensure stable catalyst support and uniform media distribution, preventing packing failure that could decrease equipment efficiency.

Furthermore, their high-density structure provides better stability during filling, preventing displacement caused by fluid impact. This enhances operational continuity and safety—especially in demanding industrial applications requiring highly durable and stable packing materials.

Contact Information

Company Name: Pingxiang Yongguang Chemical Packing Co., Ltd.

Quotation Email: lizhi@pxball.cn

Contact Person: Li Zhi

Address: Xiangdong District, Pingxiang City, Jiangxi Province, China

Purchasing Guidelines

Clarify Key Parameter Requirements:

Determine alumina content based on application (17%–45% for general use, ≥70% for high-temperature/high-pressure environments). Select suitable size (matching equipment dimensions to avoid inefficiency), and confirm temperature resistance, compressive strength, and other key technical indicators to prevent mismatches.

Verify Manufacturer Qualifications & Capability:

Choose manufacturers with certifications and extensive industry experience. Request quality inspection reports (e.g., water absorption, acid resistance). If possible, inspect production facilities or review customer cases to ensure product stability.

Confirm Pricing & Delivery Details:

Clarify whether the quotation includes VAT and freight. Understand tiered pricing (discounts for larger volumes). Confirm delivery schedules (stock/customized) and logistics arrangements—especially for hazardous material transport where specific licenses may be required.

Focus on After-Sales Service:

Ask whether technical support is provided (e.g., selection guidance) and whether return/exchange policies cover parameter mismatches. Reliable after-sales support ensures smooth operation without affecting production.

Reviews

There are no reviews yet.