Preface

Here, we have sorted out the prices and price lists of inert alumina ceramic balls, and also listed the relevant factors that affect the prices, as well as the aspects of quality that need to be noted when purchasing inert alumina ceramic balls, etc.

price list

| Price of inert ceramic balls with low aluminum content | $420 | >=4 tons

|

Shipping fee and delivery date to be negotiated. |

| The price of inert ceramic balls with medium aluminum content | $750 | >=3 tons

|

Shipping fee and delivery date to be negotiated. |

| The price of inert ceramic balls with high aluminum content | $1250 | >=2 tons

|

Shipping fee and delivery date to be negotiated. |

Factors influencing prices

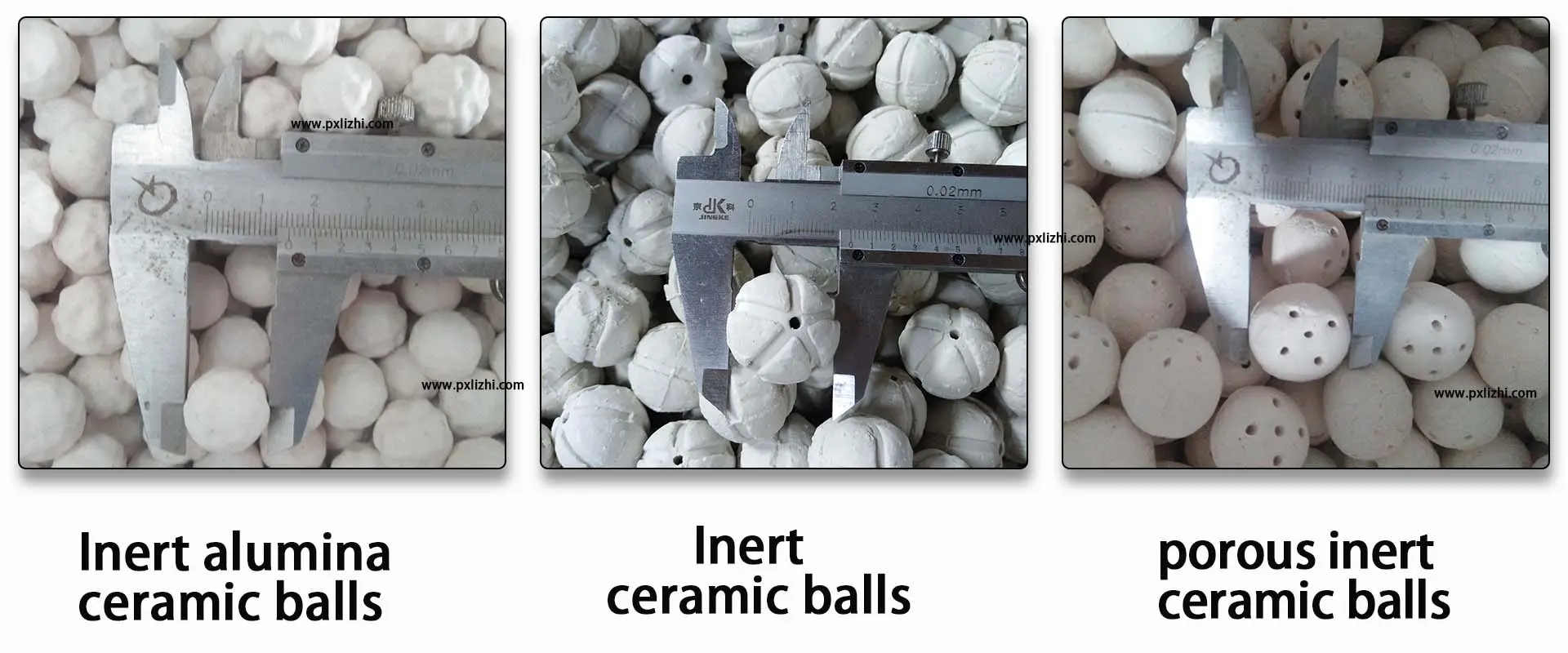

Technical requirements: For instance, the higher the content of aluminium oxide required, the more expensive the price will be. Of course, there are also other special requirements, such as the requirement for porous inert ceramic balls.

Packaging requirements: Inert ceramic balls are packaged in trays, woven bags and iron drums. Their prices are around 100 US dollars.

Purchase quantity: When the purchase quantity is large, there will definitely be more discounts. It is worth noting that when the purchase quantity is very small, sometimes the price of inert alumina ceramic balls is even lower than the freight.

Factory quotation method

E-mail: lizhi@pxball.cn

Wechat ID: pxlizhi

Website: www.pxlizhi.com

Company Name: Pingxiang Yongguang Chemical Filler Co., LTD

Problems to be noted when purchasing

Clarify the performance index requirements: Prioritize the confirmation of alumina content (such as 92%, 95%, etc., as the content directly affects strength and corrosion resistance), compressive strength (which needs to match the working condition pressure to avoid equipment blockage caused by crushing), and bulk density (related to wear resistance and service life). Require suppliers to provide third-party test reports to avoid the problem of “false labeling”.

Verify the dimensions and appearance quality: Determine the specifications of the porcelain balls (such as Φ10mm, Φ20mm, etc.) based on the filling space inside the equipment. Conduct on-site sampling inspection of the appearance – there should be no obvious cracks, missing corners, or bulges, the surface should be smooth and uniform, and the dimensional error should be controlled within ±5% of the industry standard to prevent the filling density and fluid distribution from being affected due to dimensional mismatch.

Evaluate the supplier’s qualifications and production capacity: Select a manufacturer with over 3 years of production experience and a complete production line, and verify its business license, production license and other qualifications. Inquire about production capacity and delivery cycle to avoid delays in delivery due to insufficient capacity of suppliers, which may affect the project progress. At the same time, understand its after-sales policies, such as the terms for replenishing damaged goods and returning or exchanging goods for quality issues.

Match the actual working conditions: If it is used in high-temperature and highly corrosive environments (such as chemical reaction towers), additional requirements are needed for the temperature resistance (usually above 800℃) and acid and alkali resistance test data of the ceramic balls. If it is used in high-precision filtration scenarios, the porosity of the porcelain balls also needs to be confirmed to prevent impurities from adsorbing and clogging.

Factory Introduction

We are a Chinese factory established in 2014, specializing in the production of inert ceramic balls. Due to our years of professionalism, our quality is more reliable. As we sell directly from the factory, our prices are more favorable. We can meet customers’ requirements for different specifications and sizes of inert ceramic balls, as well as different aluminum oxide contents. We can also meet the needs of emergency delivery. We offer wholesale, retail and neutral packaging services.

Reviews

There are no reviews yet.