Definition

inert aluminum oxide porcelain ball are spherical industrial ceramic fillers made by using alumina (Al₂O₃) as the core material, supplemented with a small amount of binders and other additives, through the processes of material mixing, molding, high-temperature sintering. Their core characteristic is “chemical inertness”, meaning they do not undergo chemical reactions with the gas and liquid media in the reaction system. They also possess high strength, high temperature resistance, low impurities, and low wear resistance. In industrial settings, they are mainly used in reactors and towers in fields such as petrochemicals, coal chemical industries, and environmental protection, to perform key functions such as supporting catalysts, evenly distributing gas and liquid media, buffering fluid impacts, and protecting equipment internals. They are important functional basic materials that ensure the stable and efficient operation of industrial production.

Functions and Applications

- It serves as a supporting carrier, providing layered support for catalysts or adsorbents in reactors and towers to prevent them from pulverizing or shifting due to gravity or fluid impact, ensuring the stability of the bed layer.

- It acts as a medium distributor, optimizing the gas-liquid flow path through openings, concavities, and other structures, reducing deviation and dead volume, and improving the mass transfer efficiency.

- It provides a protective buffering function, forming a protective layer at the bottom of the equipment or beside key internal components to weaken the damage to the equipment caused by fluid impact.

The applications are widely spread across various fields such as petrochemicals (such as catalyst support in hydrogenation cracking and catalytic reforming reactors), coal chemical industry (support for shift catalysts in coal-to-methanol gasifiers), environmental protection (support for adsorbents and gas-liquid distribution in desulfurization and denitrification towers), and pharmaceutical fine chemicals (reactor medium protection in high-purity scenarios). It is an important functional filler that ensures efficient, stable, and low-consumption operation of industrial production.

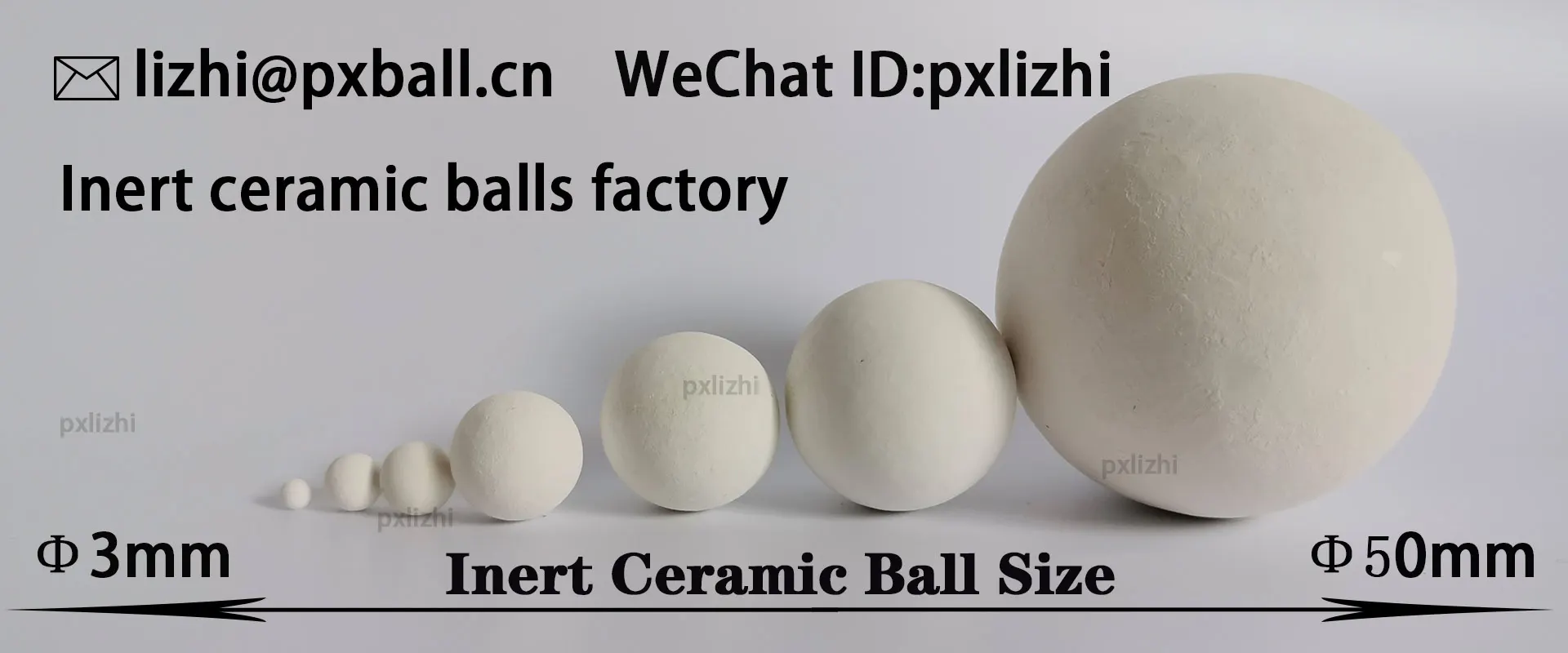

Specification dimensions

Standard production dimensions: φ1 – 2mm, φ3mm, φ6mm, φ8mm, φ10mm, φ13mm, φ16mm, φ20mm, φ25mm, φ30mm, φ40mm, φ50mm. (As we are a professional manufacturer of inert aluminum oxide porcelain ball , we not only provide specifications, but also the amount of aluminum oxide content, and other customized inert ceramic balls are available.)

Chemical composition:

| Al2O3 | SiO2 | Fe2O3 | CaO | MgO | K2O+Na2O | TiO2 |

| >92% | <3% | <1% | <4% | <0.5% | <4% | <0.1% |

Leach able Fe2O3 is less than 0.1%.

Physical composition:

| Item | Value |

| Water absorption (%) | <3 |

| Particle density (g/cm3) | 3.5 |

| Bulk density (kg/m3) | 1900 |

| Operation temp.(max) (ºC) | 1760 |

| Moh’s hardness | >7 |

Size available & Crush strength:

| Size | Crush strength KN/particle |

| 1/8″ (3mm) | >0.4 |

| 1/4″ (6mm) | >0.7 |

| 3/8″ (10mm) | >1.5 |

| 1/2″ (13mm) | >1.8 |

| 3/4″ (19mm) | >2.8 |

| 1″ (25mm) | >3.6 |

| 1-1/2″(38mm) | >5.5 |

| 2″ (50mm) | >10.5 |

Category

inert aluminum oxide porcelain ball are classified by their alumina content into different materials: feldspar type, feldspar-meliton type, meliton type, meliton-calcium oxide type, calcium oxide type, etc.

By appearance: concave-convex inert aluminum oxide porcelain ball , perforated inert aluminum oxide porcelain ball , porous inert aluminum oxide porcelain ball , solid inert aluminum oxide porcelain ball , grooved perforated inert aluminum oxide porcelain ball , microporous inert aluminum oxide porcelain ball , etc.

Comparison Table of Differences Between Low-Alumina and High-Alumina inert aluminum oxide porcelain ball

The core difference between low-alumina and high-alumina inert aluminum oxide porcelain ball lies in their alumina content. This key parameter directly determines the performance, cost, and applicable scenarios of the two types. The specific differences are as follows:

| Comparison Dimension | Low-Alumina inert aluminum oxide porcelain ball | High-Alumina inert aluminum oxide porcelain ball |

| Core Material Parameters | Alumina (Al₂O₃) content: 17%-23%Impurity content (Fe₂O₃, SiO₂, etc.): 1%-3% | Alumina (Al₂O₃) content: 92%-99%Impurity content (Fe₂O₃, SiO₂, etc.): ≤0.5% |

| Mechanical Properties | Room-temperature compressive strength: 80-120MPaAbrasion rate: 0.05%-0.1% (drum test)Impact resistance: Moderate, prone to slight pulverization under long-term high load | Room-temperature compressive strength: 250-300MPaAbrasion rate: ≤0.03% (drum test)Impact resistance: Excellent, not easy to break or pulverize under long-term high load |

| Chemical Stability | Acid-base resistance range: pH 4-10 (prone to slight corrosion in strong acid/alkali environments)Impurity leaching risk: Moderate, not suitable for high-purity medium scenarios | Acid-base resistance range: pH 1-14 (only corrodible by hydrofluoric acid)Impurity leaching risk: Extremely low, compliant with GMP standards, suitable for pharmaceutical/food-grade high-purity scenarios |

| High-Temperature Resistance | Long-term service temperature: ≤600℃High-temperature compressive strength retention rate: ≤70% (at 800℃)Coefficient of thermal expansion: 6.0×10⁻⁶/℃ | Long-term service temperature: ≤1200℃High-temperature compressive strength retention rate: ≥85% (at 800℃)Coefficient of thermal expansion: 5.0×10⁻⁶/℃ (with better thermal stability) |

| Applicable Scenarios | 1. Normal-temperature, normal-pressure, weak-corrosion scenarios (e.g., water treatment filters, support for ordinary chemical storage tanks)2. Catalyst support layer in low-load reactors (no requirements for high temperature/strong corrosion)3. Basic industrial filler scenarios sensitive to cost and without high-purity requirements | 1. High-temperature, high-pressure, strong-corrosion scenarios (e.g., hydrocracking reactors, strong acid reaction towers)2. High-purity medium scenarios (pharmaceutical intermediate synthesis, semiconductor material production)3. High-erosion/high-wear scenarios (fluidized bed reactors, pneumatic conveying pipelines)4. High-end industrial equipment (cracking furnaces, deep-sea oil and gas extraction reactors) |

Supplementary Notes:

- Core Selection Logic: If the scenario has no requirements for high temperature, strong corrosion, or high purity, and the budget is limited, low-alumina ceramic balls are preferred; if extreme working conditions (high temperature >600℃, strong acid/alkali, high-purity medium) or long-term stable operation are involved, high-alumina ceramic balls must be selected to avoid equipment failure or product contamination caused by insufficient performance.

- Reference for Transitional Type: If the demand falls between the two (e.g., medium temperature of 700℃, weak corrosion), “medium-alumina inert aluminum oxide porcelain ball ” (Al₂O₃ content: 85%-92%) can be selected to balance performance and cost, and their parameters are mostly between those of low-alumina and high-alumina ceramic balls.

Reviews

There are no reviews yet.