What are the specification sizes of inert ceramic balls? What are the tolerances? Which sizes can be customized? Why are there so many specifications? What is the table of specifications corresponding to compressive strength? All these questions are answered one by one below.

Specific Specifications of Inert Ceramic Balls

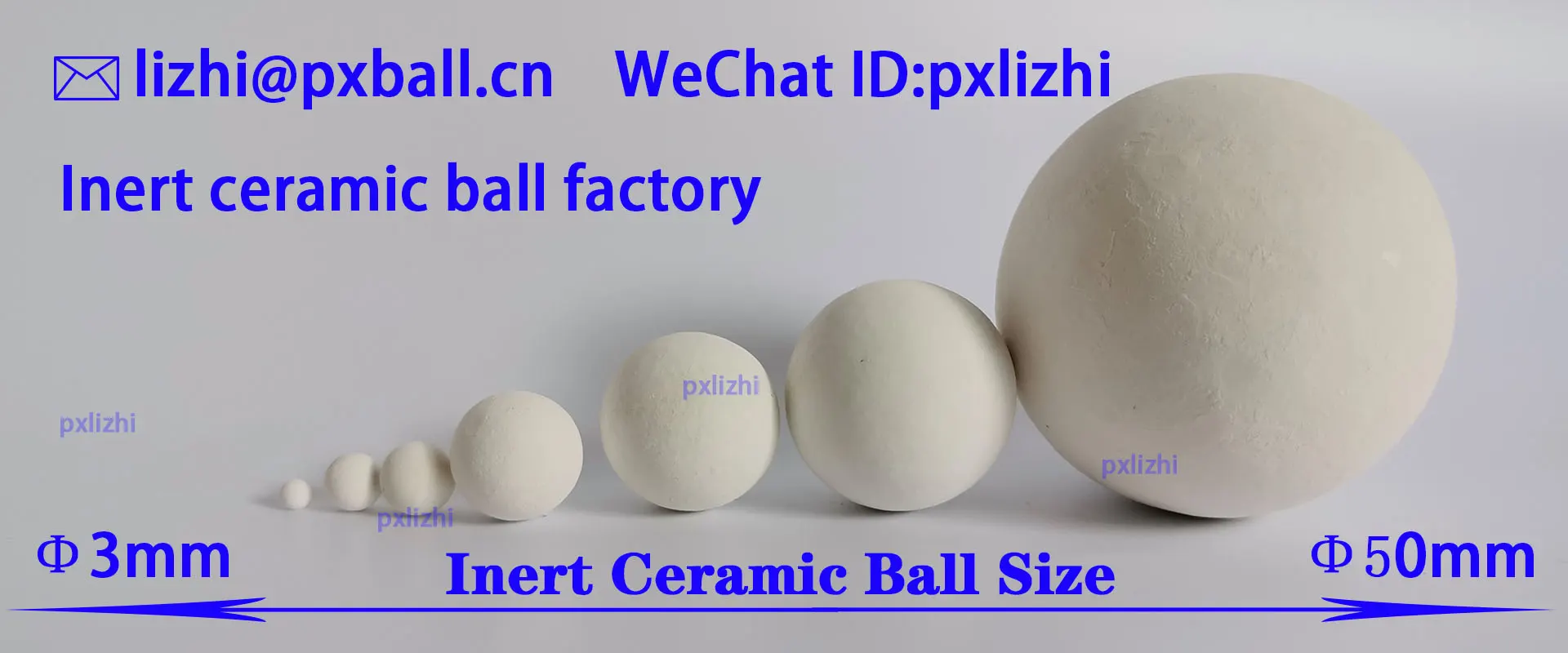

| Ball Type | Specifications (Diameter) |

| Solid Inert Ceramic Balls | Φ3mm, Φ6mm, Φ8mm, Φ10mm, Φ13mm, Φ16mm, Φ19mm, Φ25mm, Φ30mm, Φ40mm, Φ50mm |

| Perforated Inert Ceramic Balls | Φ10mm, Φ13mm, Φ16mm, Φ19mm, Φ25mm, Φ30mm, Φ40mm, Φ50mm |

| Customizable Inert Ceramic Balls | Φ1mm-2mm, Φ50mm-60mm (and other customized diameters) |

Size and Tolerance (mm)

| Size | 3/6/9 | 9/13 | 19/25/38 | 50 |

| Tolerance | ±1.0 | ±1.5 | ±2 | ±2.5 |

Specifications and Corresponding Compressive Strength Table

| Diameter | Diameter range (mm) | Crushing Strength (kg/pc) |

| 1/8 inch (3mm) | 2-4 | >40 |

| 1/4 inch (6mm) | 5-7 | >100 |

| 3/8 inch (10mm) | 9-11 | >150 |

| 1/2 inch (13mm) | 12-14 | >500 |

| 5/8 inch (15mm) | 14-17 | >700 |

| 3/4 inch (19mm) | 17-21 | >900 |

| 1 inch (25mm) | 23-27 | >1300 |

| 2 inches (50mm) | 48-52 | >2100 |

Why Are There So Many Specifications?

Inert alumina ceramic balls have a variety of specifications primarily to meet the actual needs of different industrial scenarios. In terms of size, small-sized ceramic balls can fill the tiny spaces of equipment and improve gas-liquid contact efficiency, making them suitable for processes requiring high mass and heat transfer efficiency such as precision separation and catalytic reactions. Medium and large-sized ceramic balls are more suitable as the support layer at the bottom of towers and reactors, as they can bear the weight of upper materials, ensure uniform fluid distribution, and adapt to equipment chambers of different diameters. Additionally, their specifications include parameters such as different compressive strengths and porosities to meet the working condition differences like medium corrosiveness, operating pressure, and temperature, ensuring the stable realization of core functions such as support, filtration, and dispersion in multiple fields including petrochemical, coal chemical, and environmental protection industries.

How to Select the Appropriate Specifications of Inert Alumina Ceramic Balls

- Adapt to Equipment Parameters: Choose the size based on the inner diameter, height, and internal component layout of equipment such as towers and reactors. Small-diameter equipment or areas with precision components can use small-sized ceramic balls (e.g., 3-6mm) to fill tiny spaces. The bottom support layer of large-diameter equipment should be equipped with medium and large-sized ceramic balls (e.g., 25-50mm) to avoid particle blockage of channels and ensure structural stability.

- Align with Process Function Requirements: For supporting catalysts, select ceramic balls with a slightly larger specification than the catalyst particles to prevent catalyst loss while ensuring fluid circulation. For gas-liquid dispersion or auxiliary mass and heat transfer, prioritize small to medium-sized ceramic balls with appropriate porosity to improve contact efficiency. For filtration scenarios, match ceramic balls with corresponding pore sizes and particle sizes to ensure filtration effectiveness.

- Match Operating Condition Parameters: For high-temperature and high-pressure working conditions, select ceramic balls with high compressive strength to avoid particle fragmentation. If the medium is highly corrosive, choose products of corresponding specifications with high purity and excellent corrosion resistance. Meanwhile, according to the process requirements for packing density and combined with the bulk weight characteristics of different specifications of ceramic balls, select models that meet the mass and heat transfer efficiency and equipment bearing capacity.

Reviews

There are no reviews yet.