Inert ceramic ball standard PDF download

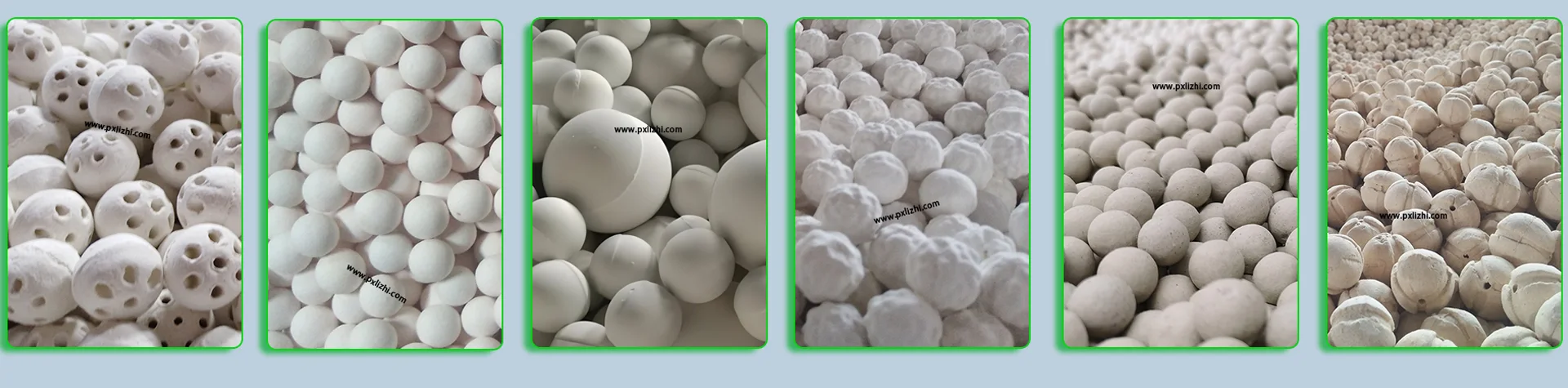

Introduction to Inert Ceramic Balls

Inert ceramic balls possess the characteristics of high strength, high chemical stability, and thermal stability. They can withstand high temperatures, high pressures, and corrosion from acids, alkalis, salts, and various organic solvents. Widely used in industries such as petroleum, chemical engineering, chemical fertilizers, natural gas, and environmental protection, inert ceramic balls serve as supporting and covering materials for catalysts in reactors. They can buffer the impact of liquids and gases entering the reactor on the catalyst, protect the catalyst, and improve the distribution of liquids and gases inside the reactor.

Technical Parameter:

| Model: | Inert Ceramic Ball | |||

| Color: | Light Grey | |||

| Shape: | Ball | |||

| Typical Technical Composition | Min.% | Max.% | Usual % | |

| SiO2 | 64 | 75 | 68.5 | |

| AI203 | 23 | 26 | 24.5 | |

| Fe203 | ****** | 1.0 | 0.9 | |

| TiO2 | ****** | 0.5 | 0.46 | |

| CaO | ****** | 0.5 | 0.42 | |

| MgO | ****** | 0.5 | 0.38 | |

| Na20 | ****** | 2 | 1.12 | |

| K20 | ****** | 3.5 | 3.28 | |

| AI203 +SiO2 | 94 | 93 | ||

Technical Data

| Item | Type 1 | Type 2 | Type 3 | Type 4 | |

| Equal to | Denstone 2000 | Denstone 57 | Denstone 99 | ||

| AL2O3 | 17-19% | 23-26% | 90% | >99% | |

| Acid resistance | >=98% | ||||

| Alkali resistance | >80% | >82% | >90% | >95% | |

| Thermal shock reistance | >=300 | >=400 | >=700 | >=800 | |

| Operation temperature (℃) | 982 | 1100 | 1350 | 1500 | |

| Bulk density(kg.m3) | 1300-1400 | 1400-1500 | 1600-1800 | >=1800 | |

| Crushing Strength (N/pellet) |

1/8”(3mm) | >350 | >350 | >510 | >510 |

| 1/4”(6mm) | >600 | >600 | >1500 | >1500 | |

| 3/8”(10mm) | >850 | >850 | >6000 | >6000 | |

| 1/2”(13mm) | >1850 | >1850 | >8000 | >8000 | |

| 5/8″(16mm) | >3600 | >3600 | >9000 | >9000 | |

| 3/4”(19mm) | >4870 | >4870 | >11000 | >11000 | |

| 1”(25mm) | >8500 | >8500 | >20000 | >20000 | |

| 1.5″(38mm) | >12000 | >12000 | >33000 | >33000 | |

| 2”(50mm) | >56000 | >56000 | >150000 | >150000 | |

| 3″(76mm) | >56000 | >56000 | >150000 | >150000 | |

Application Fields

Petrochemical Industry: In reactors for catalytic cracking, hydrofining, and other processes, they support the bottom-layer catalysts to prevent the catalysts from sinking and wearing due to gravity or medium impact. Meanwhile, they improve the distribution of oil-gas mixtures in the reactors and enhance reaction efficiency.

Chemical Fertilizer Industry: Used in towers of production equipment for synthetic ammonia, urea, etc., they support catalysts in processes such as desulfurization and decarbonization, resist corrosion from acid-alkali media, and ensure the stability of the chemical fertilizer synthesis process.

Natural Gas Industry: In natural gas purification equipment (e.g., acid removal, dehydration), they act as catalyst supports to prevent catalyst pulverization and pipeline blockage. At the same time, they can adapt to high-pressure working conditions and ensure the smooth progress of the natural gas purification process.

Environmental Protection Industry: In reactors for wastewater treatment and waste gas purification, they support adsorbents or catalysts to assist in removing water pollutants (e.g., heavy metals) and harmful components in waste gas (e.g., VOCs). Additionally, they are resistant to acid-alkali corrosion and suitable for complex treatment environments.

Types of Inert Ceramic Balls

According to the different AL2O3 content of inert alumina ceramic balls, filler ceramic balls are divided into ordinary ceramic balls, inert alumina ceramic balls, medium alumina ceramic balls, high alumina ceramic balls, 99 high alumina ceramic balls, convex concave groove perforated ceramic balls, active ceramic balls, perforated ceramic balls, microporous ceramic balls, thermal storage ceramic balls, etc.

Price of Inert Ceramic Balls

When factors such as freight, packaging, specification size, and transportation distance remain unchanged, the content of aluminum trioxide (Al₂O₃) is a key factor affecting the price of inert ceramic balls: the higher the Al₂O₃ content, the higher the price. The FOB price of low-alumina ceramic balls is around 500 US dollars, while that of high-alumina ceramic balls can reach approximately 1400 US dollars. If you want to know details about the price, specification size, and other related information of inert ceramic balls, please feel free to contact us.

Reviews

There are no reviews yet.