Preface

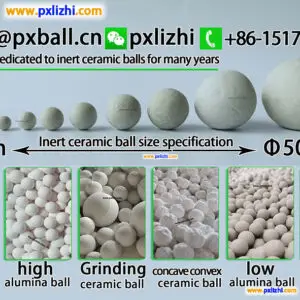

Yes, you can contact us directly for purchasing al2o3 ceramic balls. As we are a Chinese factory that has been specializing in the production of al2o3 ceramic balls for many years, we have advantages in both quality and price. Our al2o3 ceramic balls come in a wide variety of types and specifications, and we can provide emergency shipments, customized production, neutral packaging, wholesale, and retail services.

Factory Advantages

Due to its professionalism, the quality is more stable. Because it is a factory-direct sales model, the prices are more favorable. Our factory was established in 2014, covering an area of 20,000 square meters, located in Pingxiang City, Jiangxi Province, China. It is a professional manufacturer of al2o3 ceramic balls that integrates R&D, production, and sales. We have 50 employees and professional al2o3 ceramic ball testing equipment (chemical testing, physical testing). If you need to purchase al2o3 ceramic balls, you can contact us (email: lizhi@pxball.cn). We will promptly respond to your questions or quotations.

Price list

| Inert Ceramic Alumina Ball Support Media | $280-800 | Min. Order: 1 ton |

| 99% High Alumina Ball Support Media | $1.20-2 | Minimum order quantity: 500 kilograms

|

| Support Media Catalyst Protecting Media 17%-23% Inert Ceramic Balls | $280-800 | Minimum order quantity: 1 ton

|

Note: Due to the fact that the price of purchase al2o3 ceramic balls is influenced by the level of aluminum oxide content, different packaging requirements, different supply methods, and different transportation distances, please contact us for the specific price. We will reply to your questions within 1 hour to 24 hours.

Purchase Considerations

Clarify the content of alumina: This is the core indicator, directly determining performance and application. Low content (<45%) is suitable for low-temperature, weak corrosion, and scenarios with low requirements; medium-high content (70%-99%) has higher hardness, more stable chemical properties, fewer impurities, and higher temperature resistance. You need to summarize the actual requirements to select al2o3 ceramic balls.

Pay attention to physical performance parameters: Focus on checking density (affecting wear resistance and filling efficiency), Rockwell hardness (reflecting anti-wear ability), compressive strength (avoiding cracking during use), and water absorption rate (lower water absorption rate is more corrosion-resistant). The parameters need to match the usage environment.

Match specifications and appearance: Select balls with diameters suitable for the equipment cavity (commonly 3-50mm). At the same time, check the appearance for no cracks, dents, burrs, and a smooth and uniform surface. Products with better quality are more reliable and can reduce equipment wear and material contamination.

Consider details of the usage scenario: For grinding, pay attention to the roundness of the balls (affecting grinding efficiency); for chemical corrosion protection, confirm the acid and alkali resistance; in high-temperature environments, check the heat resistance stability. Avoid “general-purpose” products with insufficient adaptability.

Verify quality and after-sales: Prioritize selecting manufacturers with qualifications. Require providing quality inspection reports, especially when purchasing in large quantities, it is recommended to test the compatibility with samples before placing an order.

How to judge the quality of Al2O3 ceramic balls

Al2O3 content: The higher the content, the stronger the chemical stability and high-temperature resistance, and it is more suitable for more demanding working conditions.

Absorption rate: The lower the value, the denser the internal structure, and the better the ability to resist medium penetration corrosion.

Compressive strength: It must meet the pressure requirements of the usage scenario (such as filling in towers), there is no risk of easy cracking, and the manufacturer can be requested to provide a quality inspection report.

Surface: Smooth without burrs, cracks, depressions, or black spots, and the color is uniform.

Roundness and size: The balls are round, the size tolerance is small (usually within ±2mm), there is no obvious skew when stacked, which can reduce equipment blockage and uneven distribution of gas/liquid flow.

Reviews

There are no reviews yet.